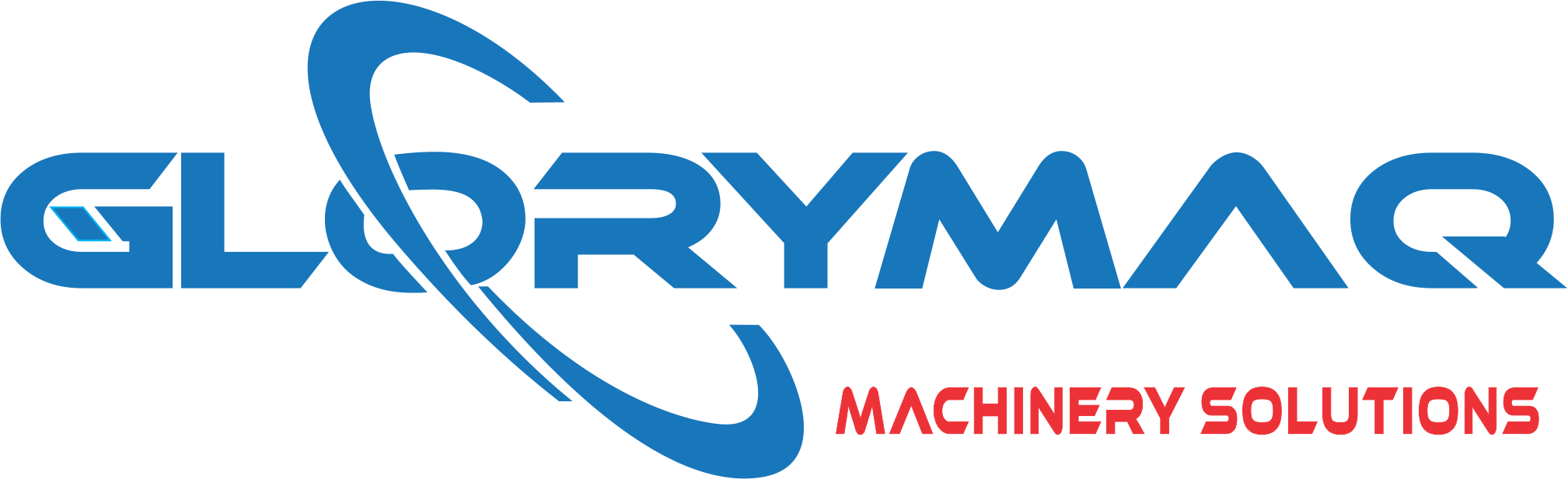

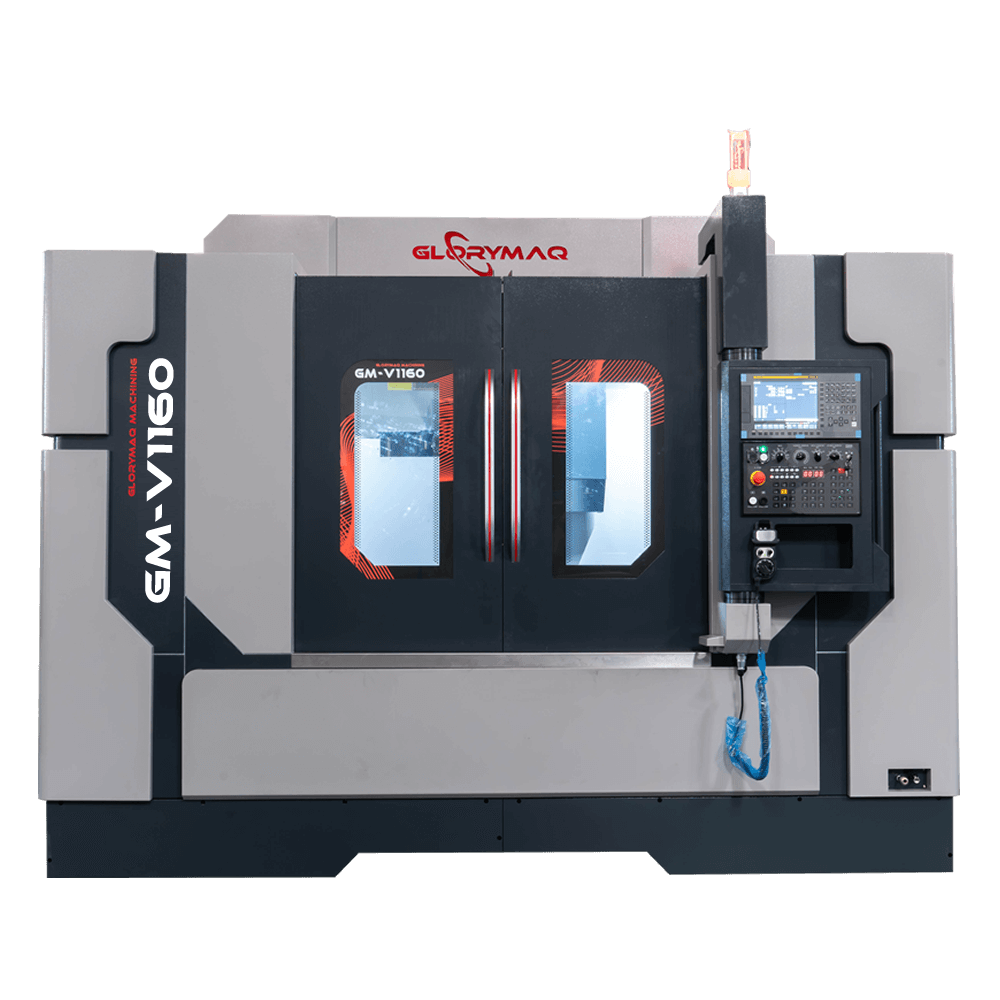

GM-5025 Portal double column gantry machining center

GM-5025 cnc gantry machining center integrated design of the column and beam has good rigidity, high machining accuracy and good stability. The main shaft is equipped with a belt-driven BT50-8000rpm main shaft as standard, and can be equipped with gear heads and electric spindles to meet different processing needs.

Classification:

Key words:

Portal double column machining center

cnc gantry machining center

GM-5025

Detail description

GM-5025 CNC Portal double column gantry machining center is in the traditional portal machine tool strong rigidity, symmetrical structure, strong bearing capacity, on the basis of improving the machine tool strong cutting ability and other advantages, and maintain high stability, high precision processing work, the introduction of advanced, rigid, dynamic,international design concept.

All use PRO/E 3D design machine tools, finite element analysis of the main structure, optimization of the moving parts design, optimize the reinforcement structure, so that its distribution of uniform and reasonable high quality equipment.

1.The main shaft is equipped with a belt-driven BT50-8000rpm main shaft as standard, and can be equipped with gear heads and electric spindles to meet different processing needs;

2.Bracket, beam and table made of high strength, high quality cast iron.

3.Our spindle has a thermal cooling compensation system to keep the temperature constant.

cnc gantry machining center for sale:market001@glorymaq.com

| Technical specification | ||

| Model | GM-5025 | |

| Axis travel | ||

| X-axis | mm | 5000 |

| Y-axis | mm | 2700 |

| Z-axis | mm | 1000 |

| Double column spacing(door width) | mm | 2700 |

| Spindle nose to table center | mm | 280-1280 |

| Table | ||

| Table size | mm | 2300*5000 |

| T slot | mm | 11-28/200 |

| Table load | kg | 15000 |

| Spindle | ||

| Spindle taper hole | Tipo | BT50 |

| Speed (optional)* | rpm | Belt 6000 |

| Spindle power | kw | 22 |

| X/Y/Z-axis servo motor transmission mode and transmission ratio | X-axis | planetary gearing: 4:1 (optional belt drive: 2.5:1) |

| Y-axis | planetary gearing: 3:1 (optional direct drive) |

|

| Z-axis | direct drive | |

| Spindle connection mode | Belt drive/Reduction box | |

| X/Y/Z motor power | kw | 7/4.5/4.5 |

| Cutting feed | m/min | 10/10/10 |

| Linear guide and ball screw (PMI/HIWIN/HSK) | ||

| Linear guide ( X / Y / Z) | mm | 55/55/Rectangular rail(two-line and one rigid rail) |

| Ball screw ( X / Y / Z) | mm | 80*20 / 63*16 / 50*10 |

| Drive shaft (X,Y,Z) | * | Belt |

| Accuracy | ||

| Positioning accuracy | mm | ±0.008/300 |

| Repeated positioning accuracy |

mm | ±0.008/300 |

| Tool changer (optional) * | ||

| Tool capacity | un | 24 / 30 |

| Optional * | ||

| System | SIEMENS-828D / MITSUBISHI-M80B / Fanuc Oi-MF Plus | |

| Chip removal machine | Including * | |

| 4 axis | Optional * | |

| Spindle center water outlet | Optional * | |

| 90° angle milling head | Optional * | |

| Automatic tool measurement function | Optional * | |

| Other | ||

| Evaluated machine weight including accessories | Kg | 47200 |

Refer to Power Requirements

| Power correspondence table |

55~90A |

220V |

60Hz |

3Φ |

25kW |

Refer to Pressure Requirements

| Pressure source pressure | Set pressure | Ambient temperature | Relative humidity | Air supply |

|

5~7bar |

5bar |

0~45℃ |

<90%RH |

380l/min |

5G COMMUNICATION

NEW ENERGY VEHICLE

A SHIP

AEROSPACE

3C ELECTRONICS

PRECISION DIE

Dongguan Glorymaq Technology Co., LTD focuses on the two core business segments of "advanced intelligent equipment" and "intelligent manufacturing services". The company's main products are: drilling and milling machining centers, vertical machining centers, horizontal machining centers, gantry machining centers, profile machining centers, CNC lathes, centering machines, precision carving machining centers, five axis machining centers and other machine tools.

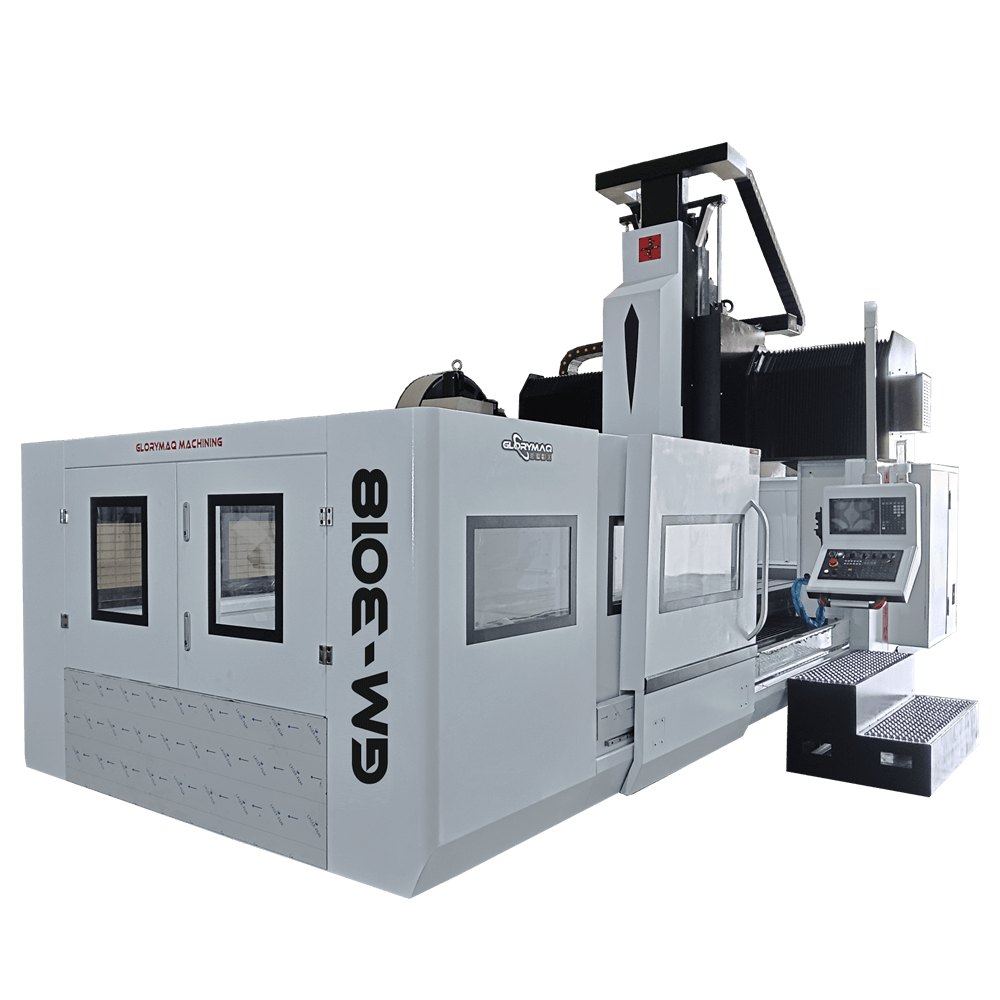

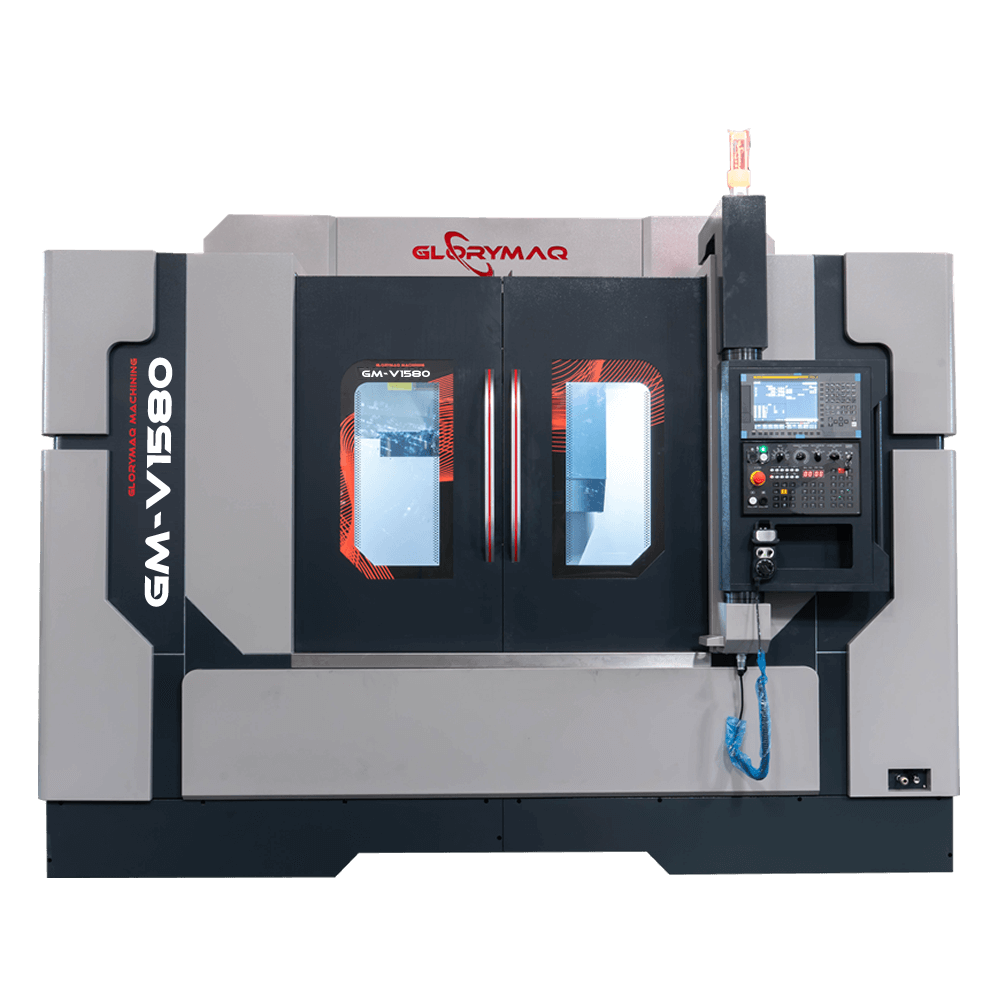

Related products

Advisory message