GM-T650 Drilling and tapping machine

Cnc drilling tapping machine center base structure adopts six-point support design,which can improve rigidity and vibration resistance of the machine, and ensure good stability during the processing period.The high-speed servo tool changer is fast and stable, which can reduce the tool changing time and non-processing time

Classification:

Key words:

Drilling and tapping machine

cnc drilling tapping machine center

GM-T650

Detail description

Mechanical characteristics

Cnc drilling tapping machine center base structure adopts six-point support design,which can improve rigidity and vibration resistance of the machine, and ensure good stability during the processing period.

The high-speed servo tool changer is fast and stable, which can reduce the tool changing time and non-processing time.

Fully enclosed shield design, backwashing with complete chip removal functions and high reliability.

High-speed and high-rigidity tapping.

Clamping arm tool library for quick and accurate tool replacement, suitable for small diameter drilling holes.

1.High rigidity.

2.Design of high rigid bracing structure.

3.High efficiency.

4.Direct spindle transmission system.

5.Save space.

6.The machine takes up little space.

After various heat treatment, the precision of the machine is effectivefor a long time, and the six points support to ensure high precision displacement performance.

The front knife library provides the speed of the tool replacement, which effectively improves the efficiency and reliability of production.

Fully enclosed protective cover design, backwash and chip removal function, high reliability.

Scope of application

Precision parts, mobile phones, 3C products

| Technical specification | ||

| MODEL | GM-T650 | |

| Axis travel | ||

| X,Y,Z axes | mm | 600*450*300 |

| Distance from spindle nose to worktable | mm | 150-450 |

| Table | ||

| Table size | mm | 700*420 |

| T slot | mm | 14T*3*125 |

| Max.table load | kg | 250 |

| Coupling | ||

| Spindle taper hole | BT | 30 |

| speed | rpm | 20000 |

| spindle motor | kw | 5.5 |

| Spindle connection mode | Direct drive | |

| Three-axis connection mode | ||

| Three-axis motor power | kw | 1.5/1.5/3 |

| Transmission mode | Direct drive | |

| Linear guide and ball screw (PMI/HIWIN/HSK) | ||

| Linear guide ( X / Y / Z) | mm | 30 |

| Ball screw ( X / Y / Z) | mm | 28*16/28*16/32*16 |

| Rapid traverse (X / Y / Z) | m/min | 48 |

| Accuracy | ||

| Positioning accuracy | mm | ±0.008/300 |

| Repeated positioning accuracy | mm | ±0.008/300 |

| Automatic tooling change system | ||

| Automatic tool change type | Arm-type/servo tool | |

| Tool capacity | un | 21 |

| max tool weight | kg | 8 |

| max tool length | mm | 200 |

| Maximum tool diameter (full tool/adjacent empty tool) | mm | 160 |

| Tool magazine type | 21T | |

| Optional * | ||

| System | SIEMENS-828D / MITSUBISHI-M80B / Fanuc Oi-MF Plus | |

| 4 axis | Optional * | |

| Automatic tool measurement function | Optional * | |

| Other | ||

| Size | mm | 1900*2100*2300 |

| Evaluated machine weight including accessories | kg | 3,500 |

Refer to Power Requirements

| Power correspondence table |

55~90A |

220V |

60Hz |

3Φ |

25kW |

Refer to Pressure Requirements

| Pressure source pressure | Set pressure | Ambient temperature | Relative humidity | Air supply |

|

5~7bar |

5bar |

0~45℃ |

<90%RH |

380l/min |

5G COMMUNICATION

NEW ENERGY VEHICLE

A SHIP

AEROSPACE

3C ELECTRONICS

PRECISION DIE

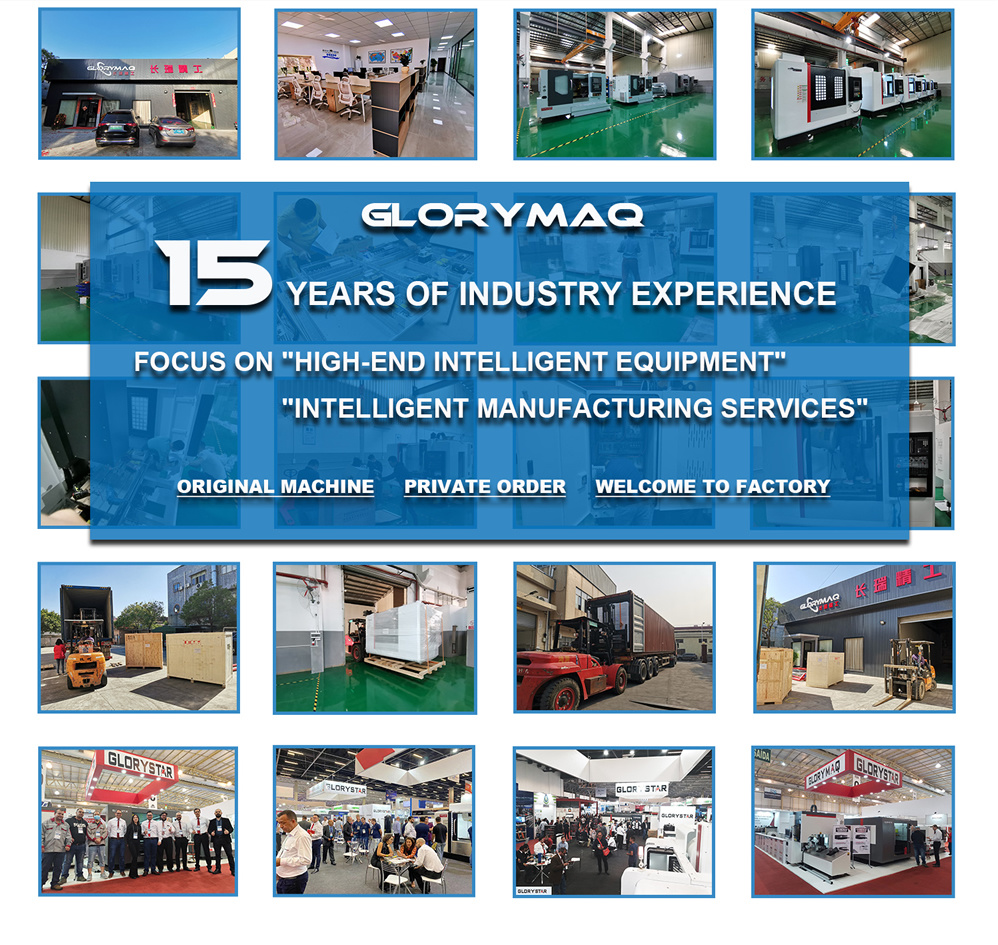

Dongguan Glorymaq Technology Co., LTD focuses on the two core business segments of "advanced intelligent equipment" and "intelligent manufacturing services". The company's main products are: drilling and milling machining centers, vertical machining centers, horizontal machining centers, gantry machining centers, profile machining centers, CNC lathes, centering machines, precision carving machining centers, five axis machining centers and other machine tools.

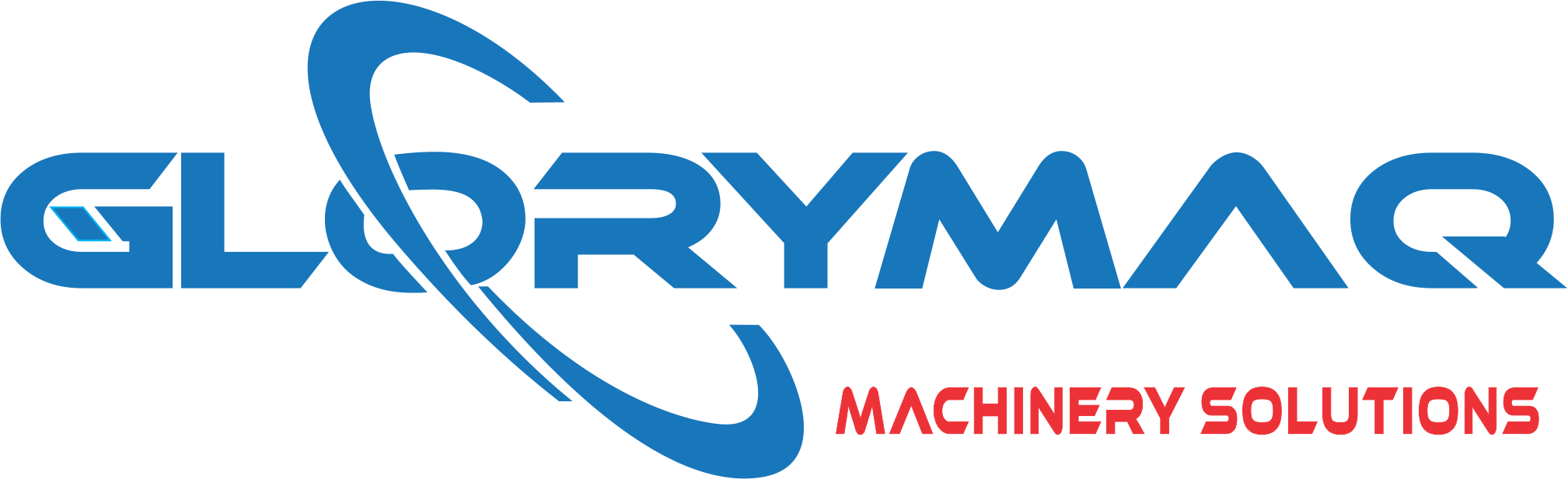

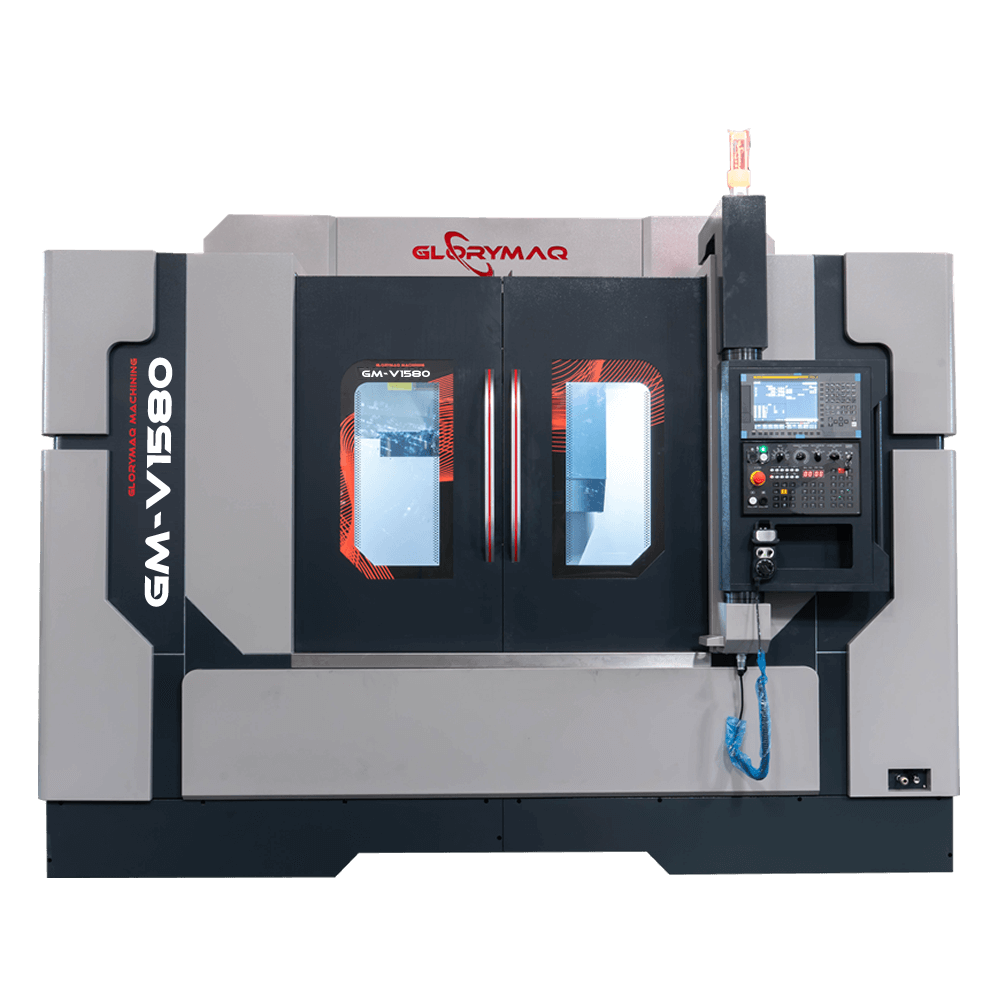

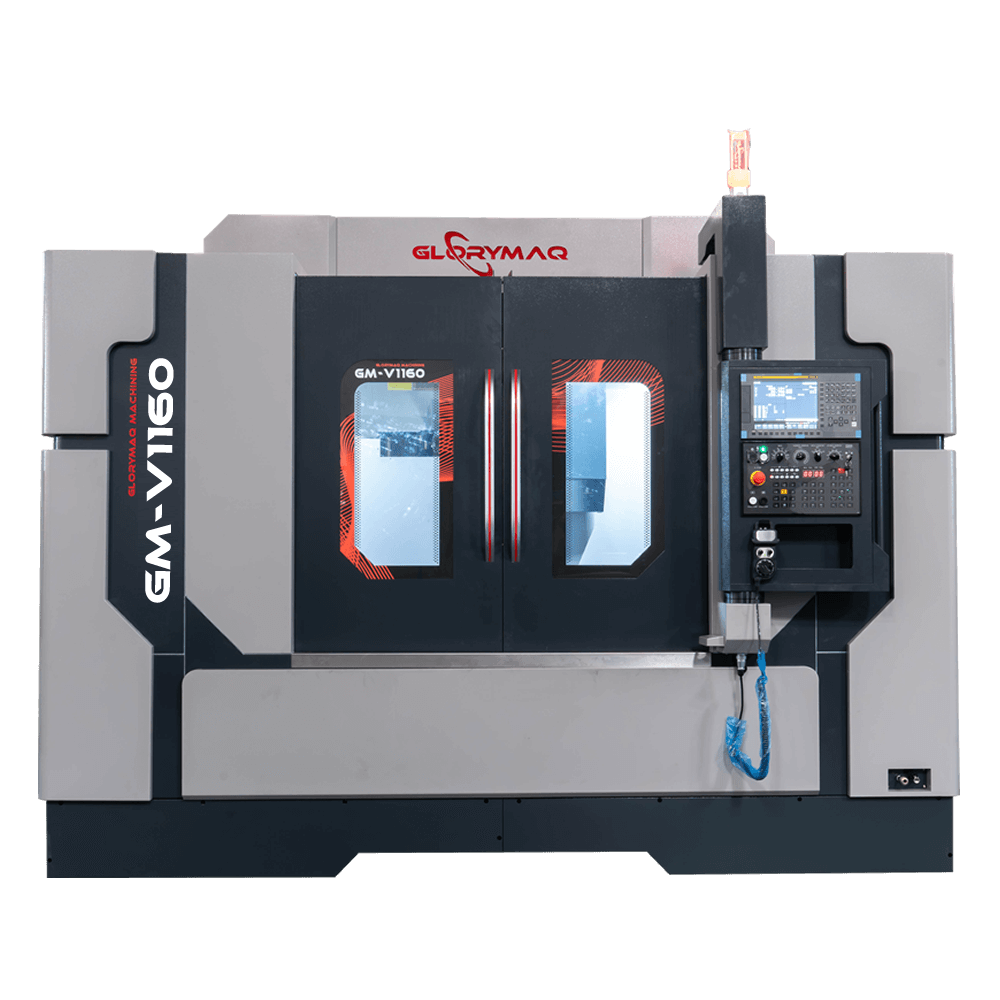

Related products

Advisory message