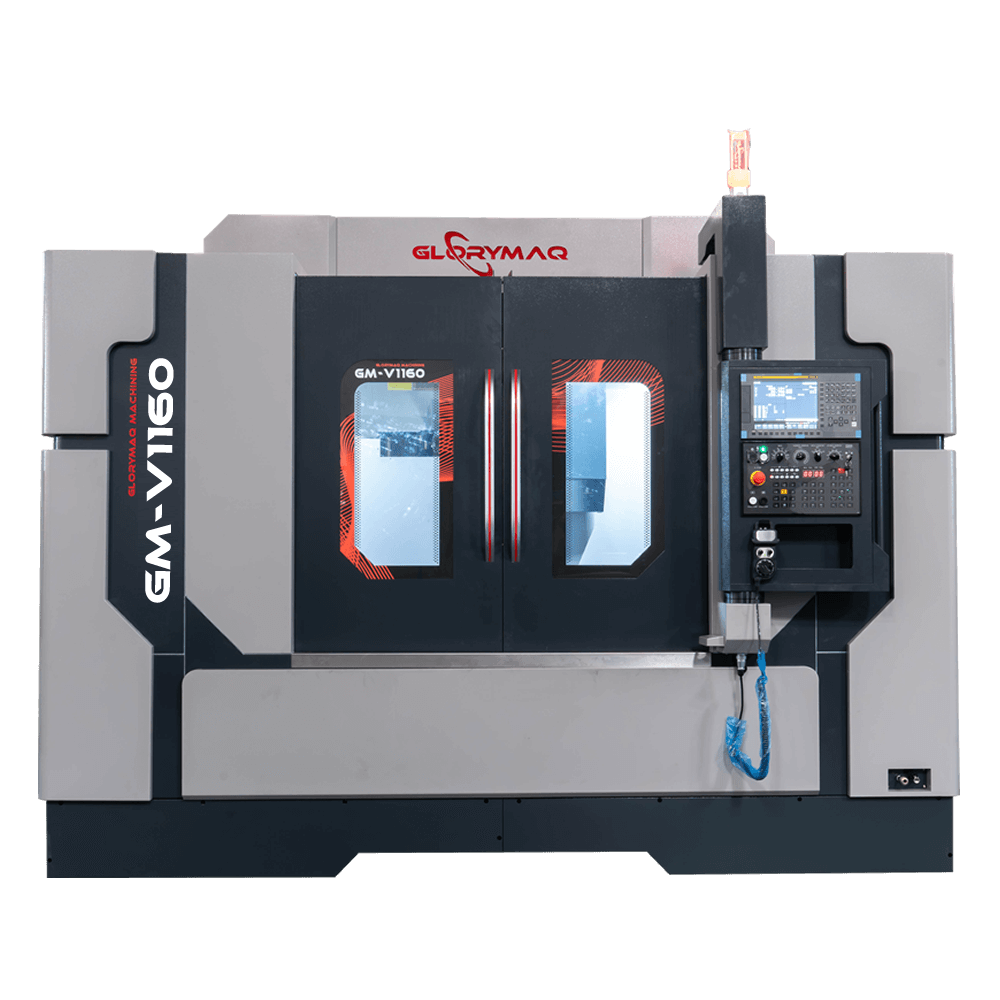

GM-V1160 Vertical Machining Center

VMC1160 Vertical machining center high-speed V series can complete milling, boring, drilling, tapping and thread cutting processes.The pitch between the screws is 12mm, and the linear speed and load capacity of the screw is large.The operation interface is simple, intuitive and easy to operate, and it can realize automatic processing through pre-written programs to improve production efficiency.

Classification:

Key words:

Vertical Machining Center

cnc vertical machining center for sale

VMC1160

Detail description

| Technical specification | ||

| MODEL | GM-V1160 | |

| Axis travel | ||

| X,Y,Z axes | mm | 1100*600*600 |

| Distance from spindle center to column | mm | 650 |

| Distance from spindle nose to worktable | mm | 120-720 |

| Table | ||

| Table size | mm | 1200*600 |

| T slot | mm | 18T*5*100 |

| Max.table load | kg | 800 |

| Coupling | ||

| Spindle taper hole | BT | BT40 |

| Optional speed* | rpm | 10000/12000 (Optional)* |

| Spindle motor | kw | 11 |

| Spindle connection mode | Belt drive/Direct drive | |

| Three-axis connection mode | Direct drive | |

| Three-axis motor power X/Y/Z | kw | 3/3/3 |

| Linear guide and ball screw (PMI/HIWIN/HSK) | ||

| Linear guide ( X / Y / Z) | mm | 45/45/45 |

| Ball screw ( X / Y / Z) | mm | 40*12 |

| Max.Rapid traverse ( X / Y / Z) (Use of this extreme parameter for prolonged durations is not advisable.) | m/min | 36/36/36 |

| Accuracy | ||

| Positioning accuracy | mm | ±0.008/300 |

| Repeated positioning accuracy | mm | ±0.008/300 |

| Tool changing device (automatic) | ||

| Tool capacity | un | 24 |

| max tool weight | kg | 15 |

| max tool length | mm | 300 |

| Maximum tool diameter (full tool/adjacent empty tool) | mm | 200 |

| tool magazine form | BT40 | |

| Optional * | ||

| System | SIEMENS-828D / MITSUBISHI-M80B / Fanuc Oi-MF Plus | |

| Chip removal machine | Optional * | |

| 4 axis | Optional * | |

| Spindle center water outlet | Optional * | |

| Automatic tool measurement function | Optional * | |

| Other | ||

| Size | mm | 3200*2270*2520 |

| Evaluated machine weight including accessories | kg | 6100 |

Refer to Power Requirements

| Power correspondence table |

55~90A |

220V |

60Hz |

3Φ |

25kW |

Refer to Pressure Requirements

| Pressure source pressure | Set pressure | Ambient temperature | Relative humidity | Air supply |

|

5~7bar |

5bar |

0~45℃ |

<90%RH |

380l/min |

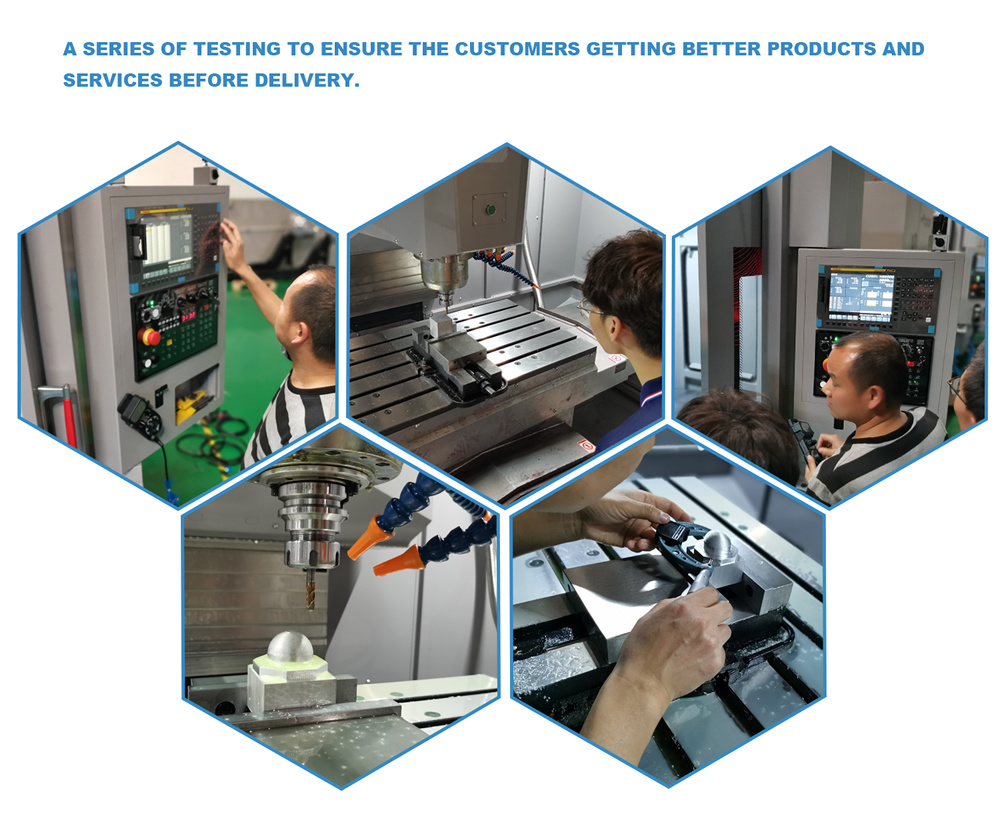

1. Superior Precision: The V1160 CNC Vertical Machining Centre ensures exceptional accuracy and precision in handling various machining tasks, delivering outstanding results each time.

2. Efficient Production: Boost your productivity with the V1160 CNC Vertical Machining Centre, designed to handle a wide range of machining tasks effortlessly, making your production processes more efficient and time-saving.

3. User-friendly Operation: Experience seamless operation with the V1160 CNC Vertical Machining Centre's user-friendly interface, allowing for easy and intuitive control, even for users with limited technical expertise.

4. Customized Solutions: Addressing the unique needs of our customers, the V1160 CNC Vertical Machining Centre provides personalized solutions, empowering you to achieve your specific machining goals with ease and efficiency.

5. Reliable After-sales Support: Rest assured with our dedicated after-sales support, ensuring prompt assistance and reliable technical support to maximize the long-term performance and productivity of your V1160 CNC Vertical Machining Centre.

CNC Vertical machining center high-speed V series can complete milling, boring, drilling, tapping and thread cutting processes.

Vertical machining center high-speed V series is suitable for machining various parts and products with high hardness, high precision, high surface quality and high efficiency, This type of machining center usually has high speed, high precision, high reliability, high automation and flexible machining capability, which is suitable for small batch, multi-species and high precision machining needs.

1、The spindle and table are vertically aligned for high cutting forces and rigidity, making it suitable for machining heavy, high-strength materials and large workpieces.

2、GM-V series is arm type tool magazine, with automatic tool changing system, it can change tools of different shapes and sizes quickly and accurately to meet different machining needs.

3、High-speed, high-precision positioning and motion control capability, with three-axis high-speed displacement of 36 m/min, which can save non-machining time.

4、The pitch between the screws is 12mm, and the linear speed and load capacity of the screw is large.

5、The operation interface is simple, intuitive and easy to operate, and it can realize automatic processing through pre-written programs to improve production efficiency.

6、High speed silent screw and silent linear guide make the thermal displacement smaller,high precision.

7、The connection between motor and spindle is direct connection, with large speed and brightness.

cnc vertical machining center for sale:market001@glorymaq.com Get Nice Factory Price for vmc1160

5G COMMUNICATION

NEW ENERGY VEHICLE

A SHIP

AEROSPACE

3C ELECTRONICS

PRECISION DIE

Dongguan Glorymaq Technology Co., LTD focuses on the two core business segments of "advanced intelligent equipment" and "intelligent manufacturing services". The company's main products are: drilling and milling machining centers, vertical machining centers, horizontal machining centers, gantry machining centers, profile machining centers, CNC lathes, centering machines, precision carving machining centers, five axis machining centers and other machine tools.

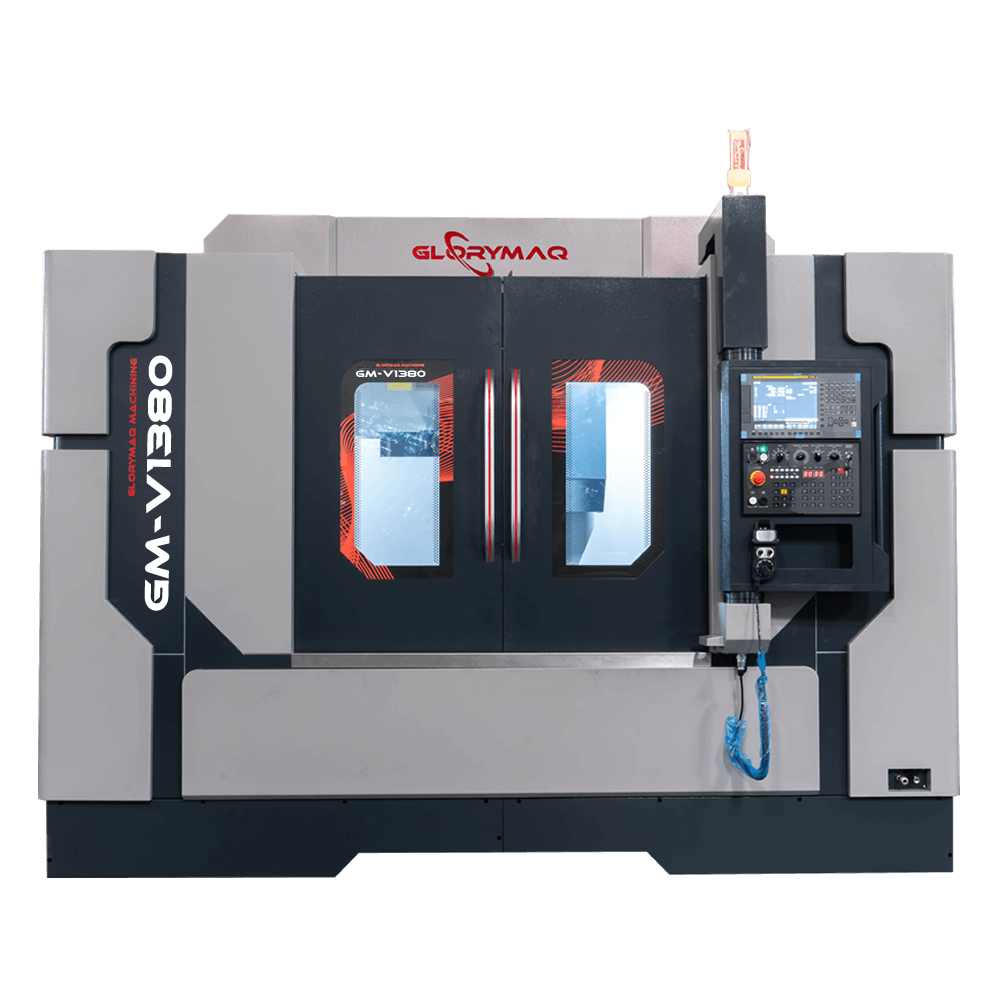

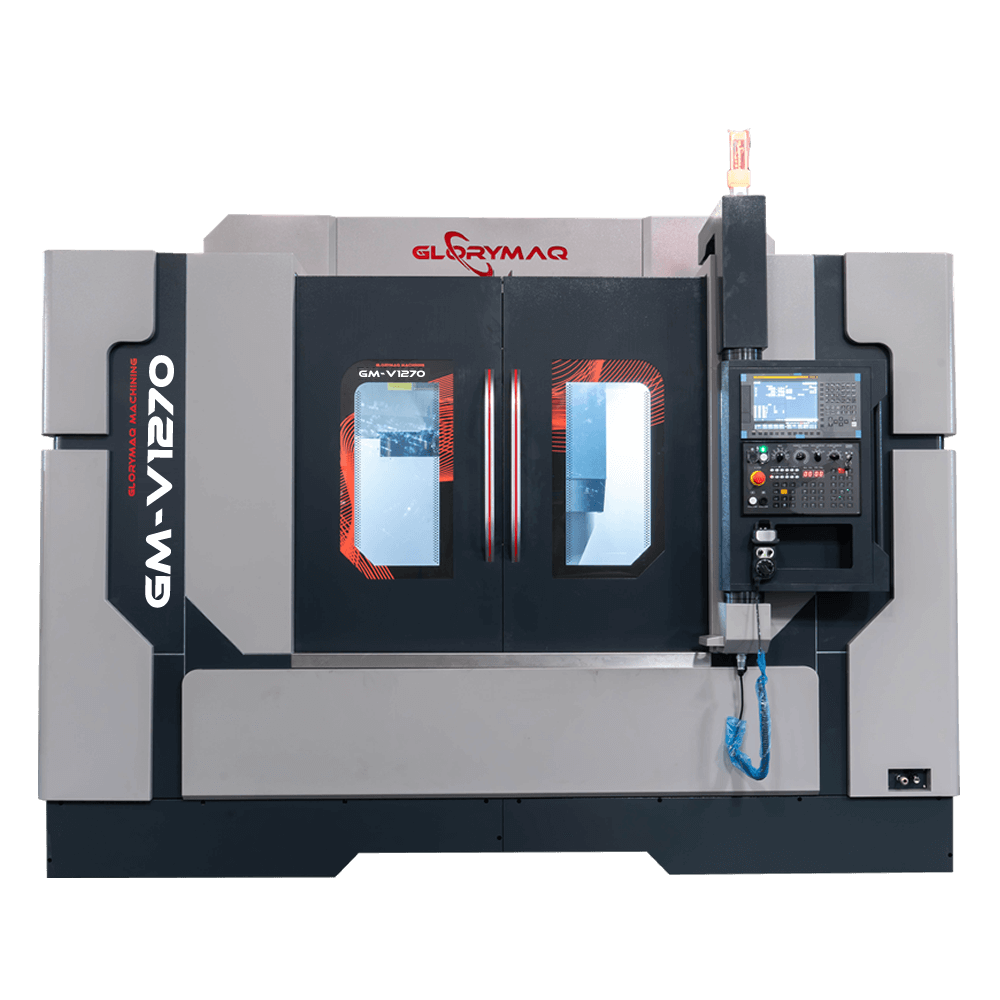

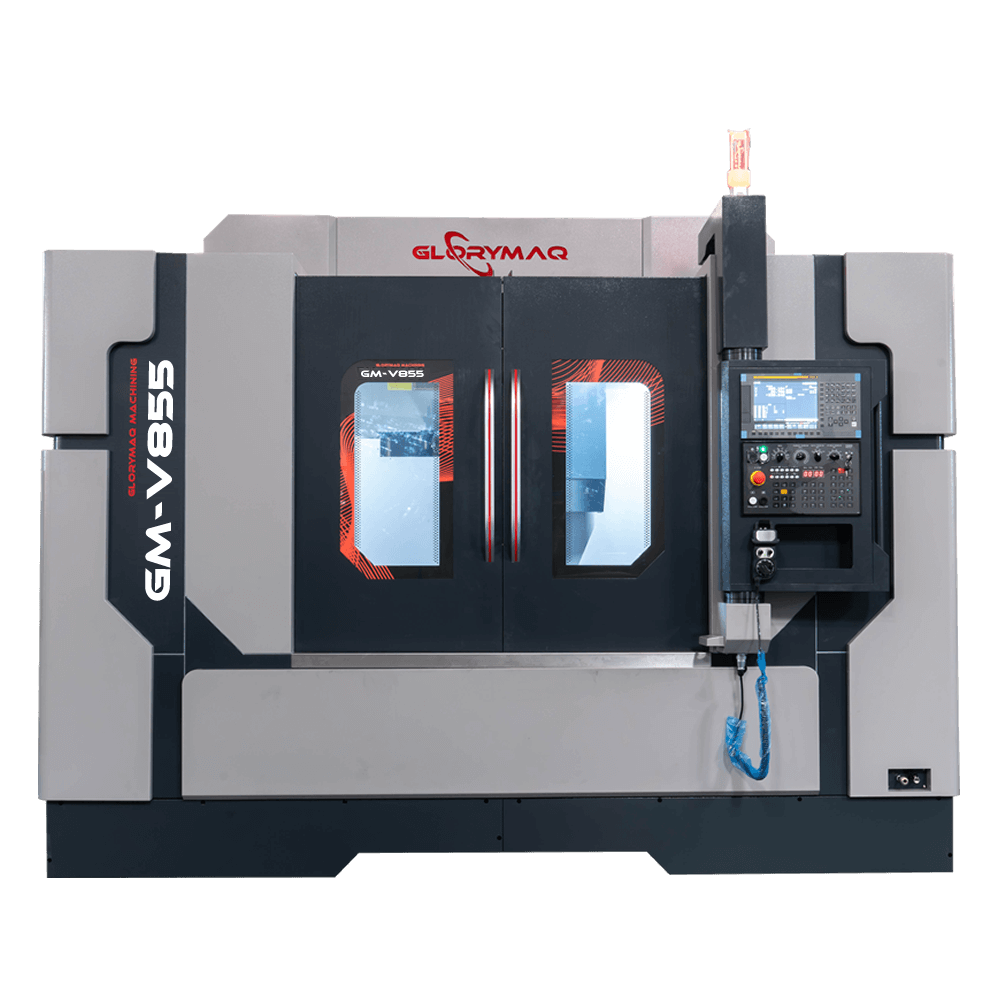

Related products

Advisory message