GM-G650 Engraving machining center

The precision cnc engraving machine is equipped with high-speed, high-torque, high-precision motorized spindle, which can meet the needs of high-speed machining and ensure accuracy. It has the characteristics of high machining precision, low vibration and low noise.

Classification:

Key words:

Engraving machining center

cnc engraving machine

CNC engraving and milling machine

Metal engraving machine

Detail description

| Technical specification | ||

| MODEL | GM-G650 | |

| Axis travel | ||

| X-axis | mm | 600 |

| Y-axis | mm | 500 |

| Z-axis | mm | 250 |

| Table | ||

| Table size | mm | 500*600 |

| T slot | mm | 18T*5*100 |

| Table load | kg | 300 |

| Vertical coupling | ||

| Spindle taper hole/mounting size | BT/HSK | BT30 HSK-E40 |

| Speed | rpm | 24000 |

| Spindle power | kw | 5.5 |

| Spindle connection mode | Motorized spindle | |

| Three-axis connection type(X/Y/Z) | Direct drive | |

| Three-axis motor power(X/Y/Z) | kw | 1.3/1.3/1.3 |

| Linear guide and ball screw (PMI/HIWIN/HSK) | ||

| Linear guide (X/Y/Z) | mm | XY:30 Z:25 |

| Ball screw (X/Y/Z) | mm | 32*5 |

| Rapid traverse (X/Y/Z) | m/min | 15 |

| cutting speed | m/min | 8 |

| Accuracy | ||

| Positioning accuracy(X/Y/Z) | mm | ±0.008/300 |

| Repeated positioning accuracy(X/Y/Z) | mm | ±0.008/300 |

| Optional * | ||

| System | SYNTEC 22MA / MITSUBISHI E80 | |

| Tool Magazine(Optional)* | ||

| other | ||

| Size | mm | 1800*1900*2200 |

| Evaluated machine weight including accessories | kg | 3,200 |

Refer to Power Requirements

| Power correspondence table |

55~90A |

220V |

60Hz |

3Φ |

25kW |

Refer to Pressure Requirements

| Pressure source pressure | Set pressure | Ambient temperature | Relative humidity | Air supply |

|

5~7bar |

5bar |

0~45℃ |

<90%RH |

380l/min |

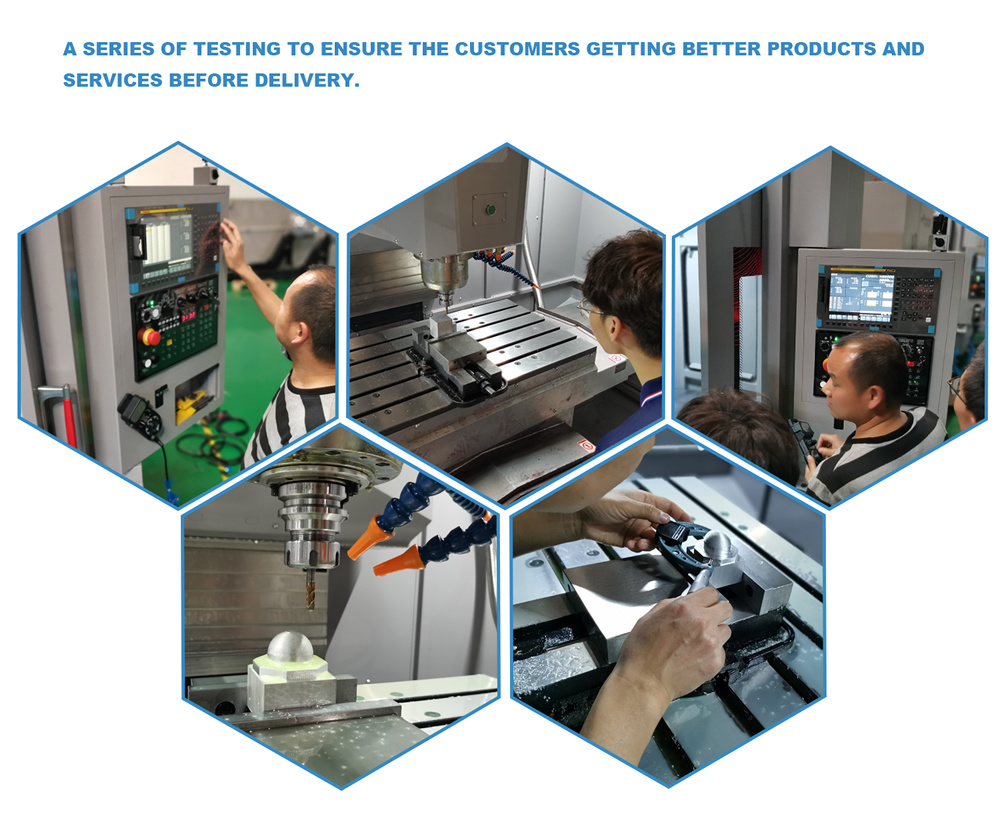

Machine tool adopts unique beam and bed integration technology, gantry type high rigid structure, to ensure the machine precision, long service life, strong impact resistance.

Three axis adopts high precision linear guide rail and imported ball shaft, wear-resistant, small friction coefficient, high positioning accuracy .

Adopt Japanese NSK bearing and imported coupling.

High speed, high torque, high precision motorized spindle, to meet the needs of high-speed machining, to ensure accuracy, with high machining precision, low vibration, low noise characteristics.

The driving system adopts Japan Yaskawa, Japan Sanyo AC drive servo system, stable operation, superior acceleration performance,low noise, high control precision.

CNC engraving and milling machine price list:market001@glorymaq.com

Master standard configuration:

Three-axis bearing (Japan NSK)

High frequency inverter

Built-in motorized spindle

Controller (for cleaning spindle and guides)

Pulse clamp

Rolled ball spindles for all three shafts

(Dewan ShanghaiYintai/Intime)

Three axis travel limit closed

Centralized automatic lubrication system

Triple shaft coupling (German system)

Yaskawa servo motor in Japan

Automatic tool configuration instrument

Selective configuration:

Tool Magazine (BT30-8T-BT30-12/16T)

Graphite filtration system

Main shaft power 7.5KW

Optional high precision Siemens 828D high speed control

High speed Shirong speed

5G COMMUNICATION

NEW ENERGY VEHICLE

A SHIP

AEROSPACE

3C ELECTRONICS

PRECISION DIE

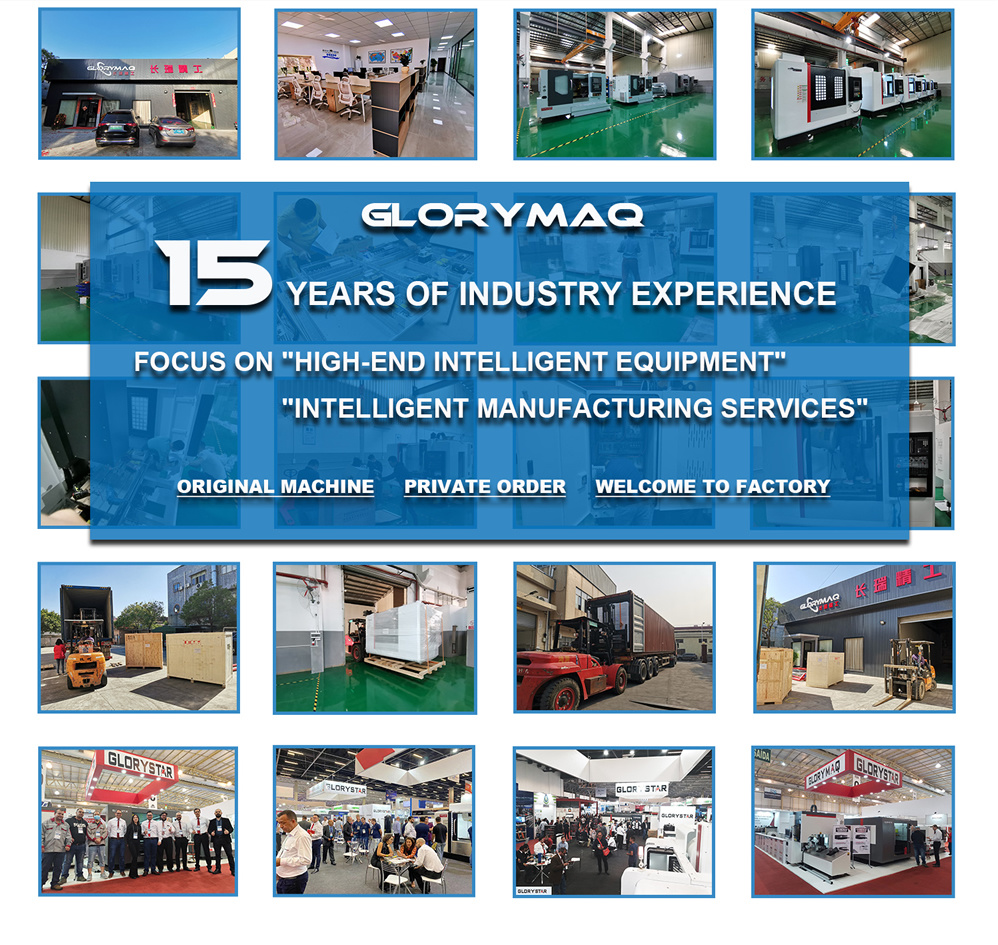

Dongguan Glorymaq Technology Co., LTD focuses on the two core business segments of "advanced intelligent equipment" and "intelligent manufacturing services". The company's main products are: drilling and milling machining centers, vertical machining centers, horizontal machining centers, gantry machining centers, profile machining centers, CNC lathes, centering machines, precision carving machining centers, five axis machining centers and other machine tools.

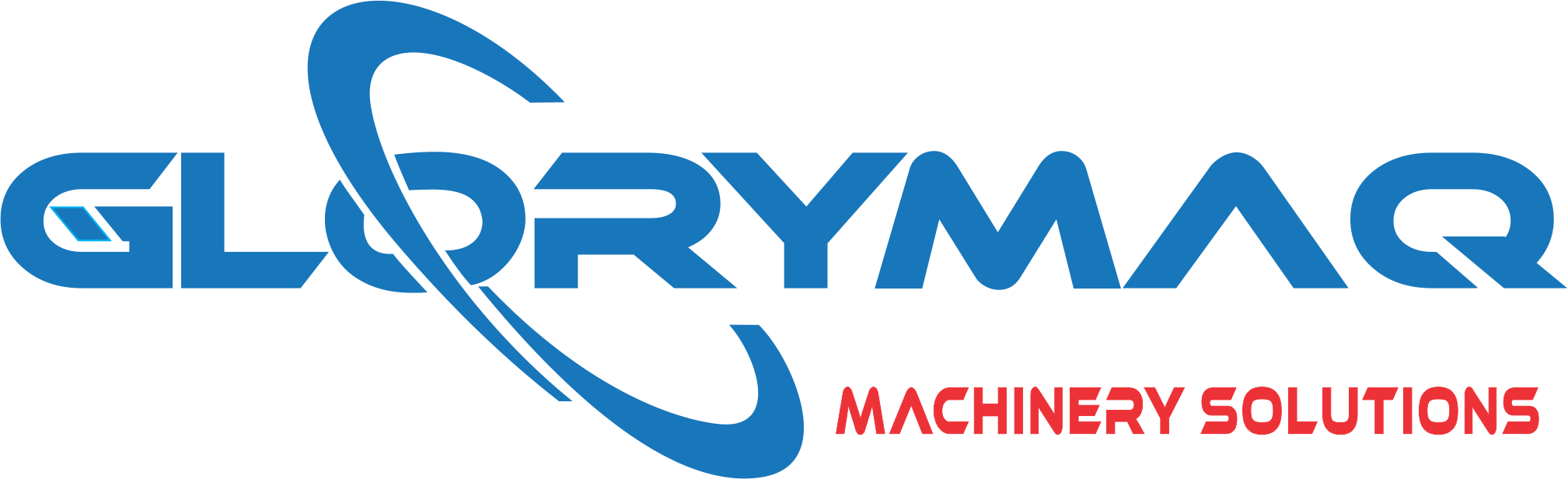

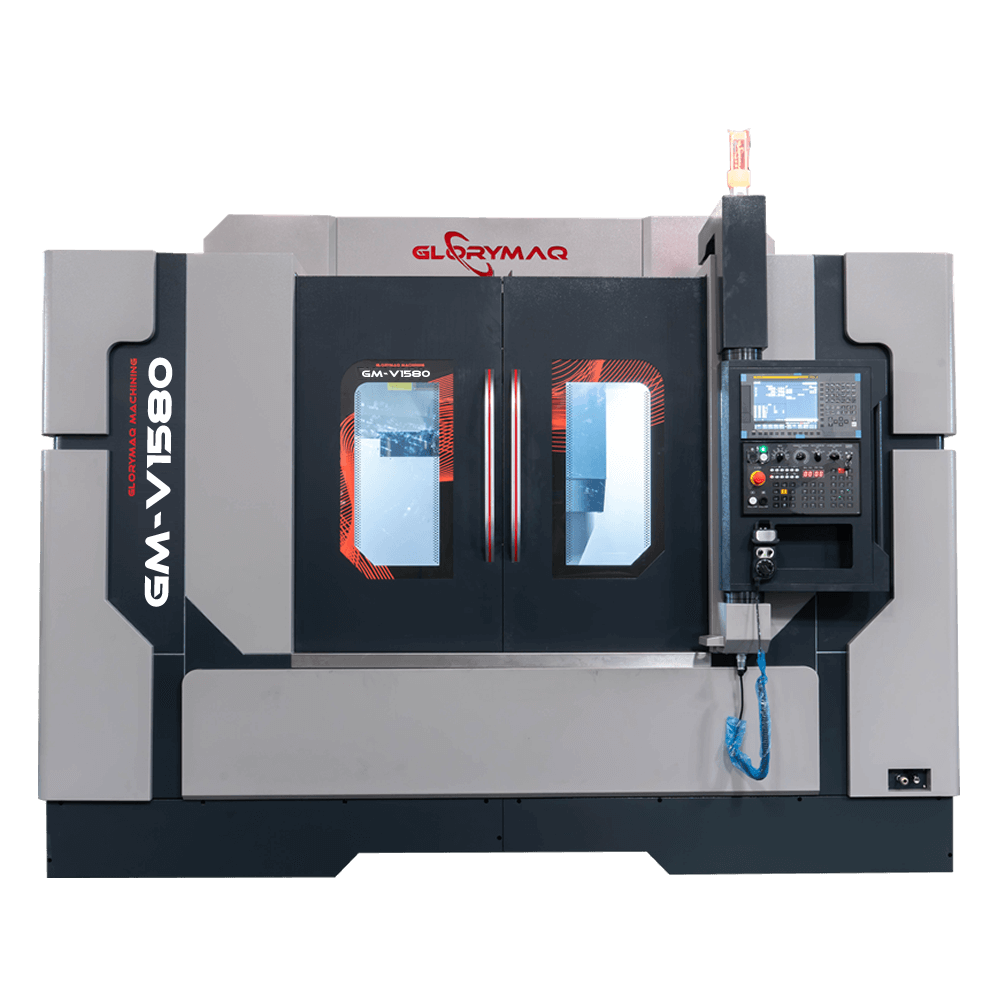

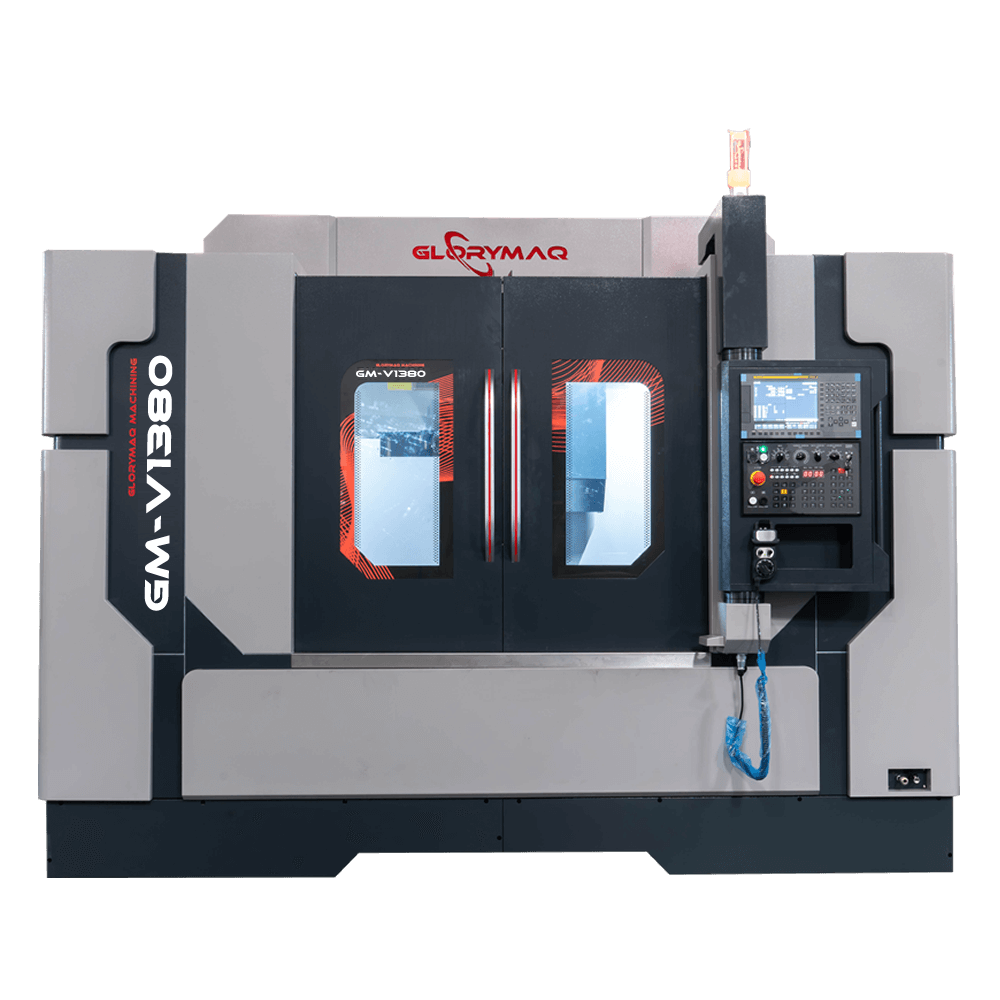

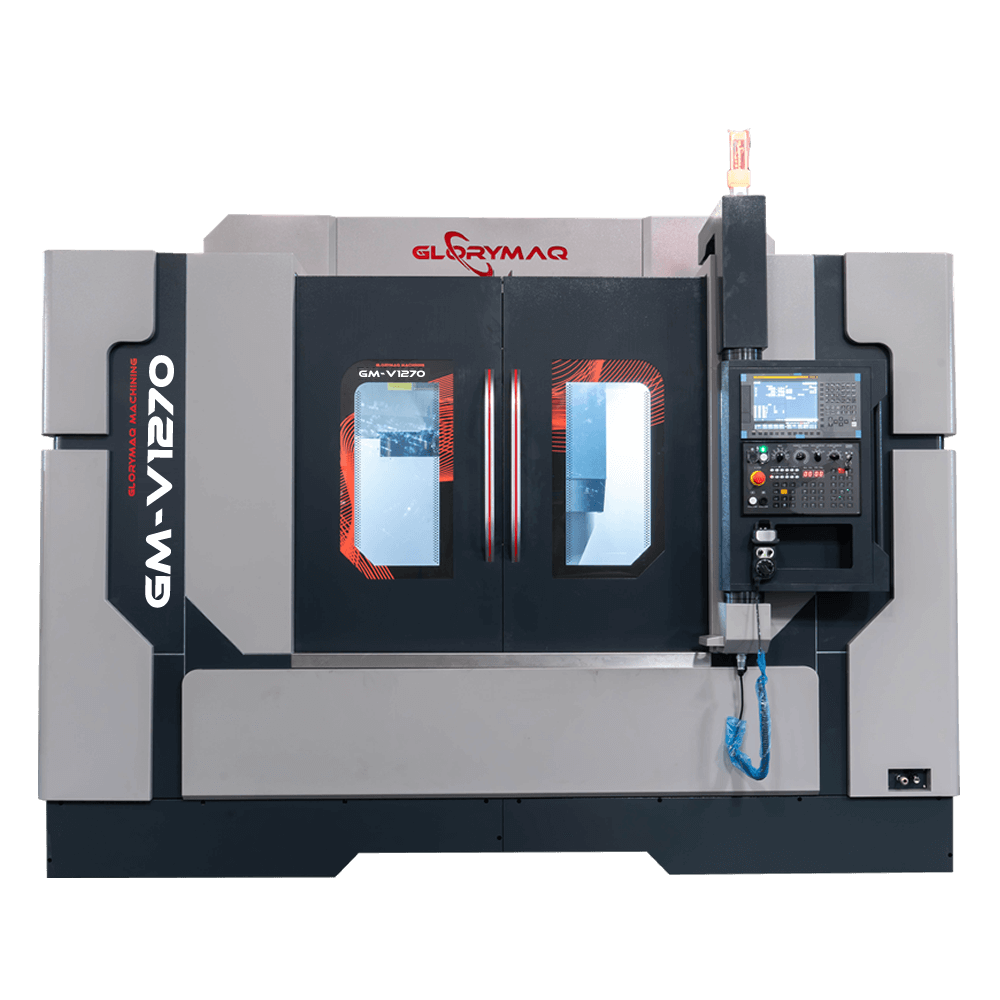

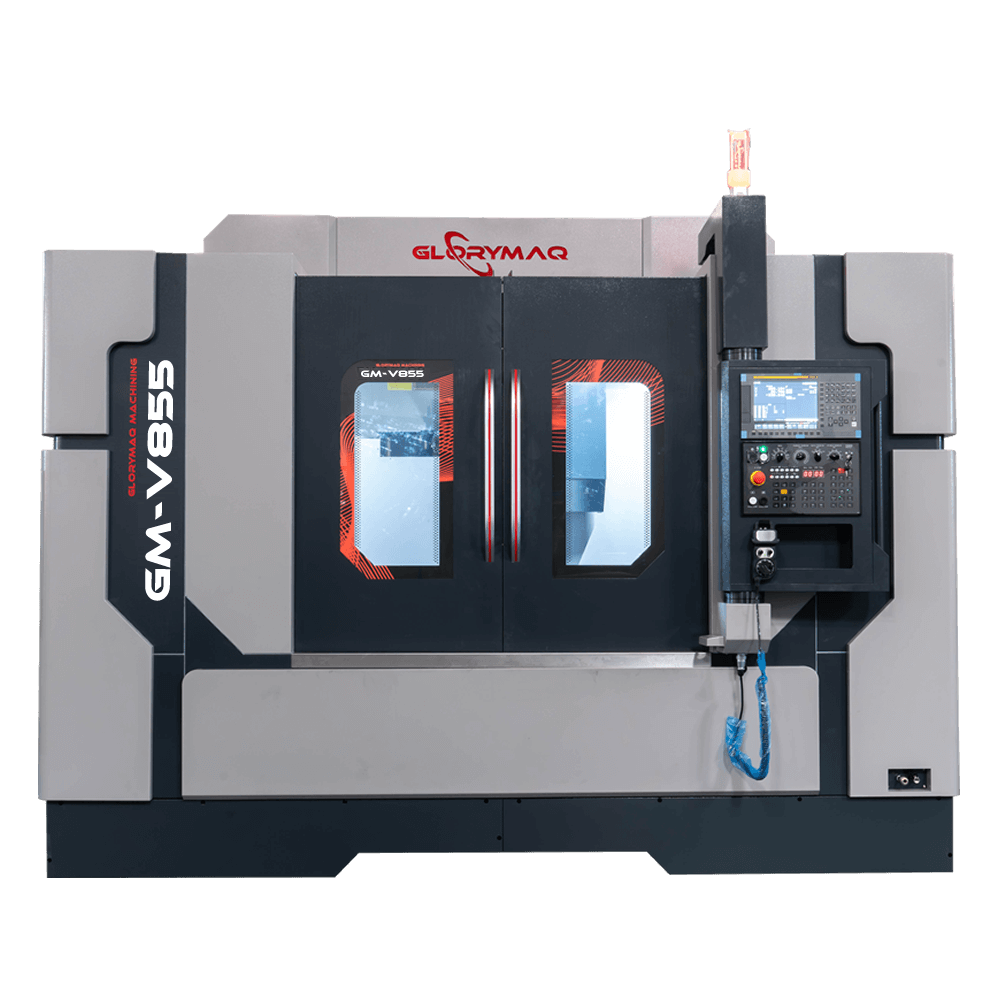

Related products

Advisory message