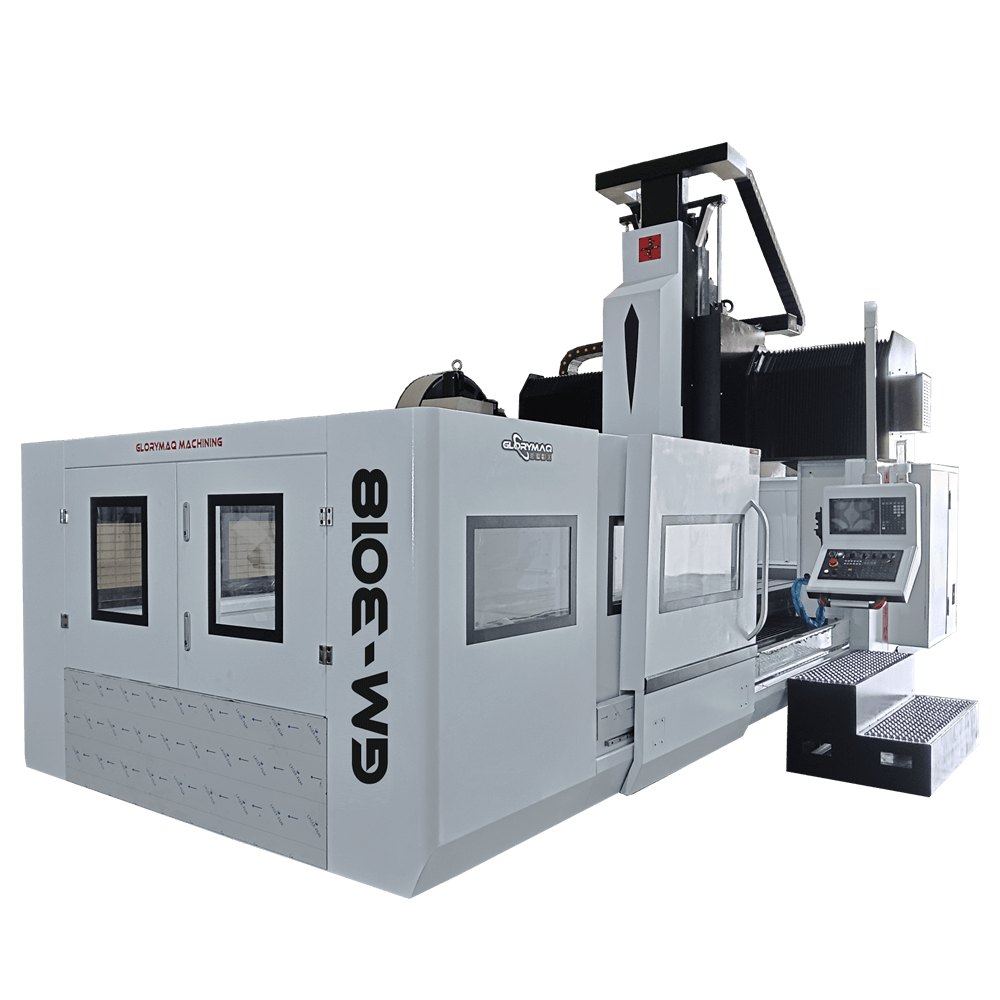

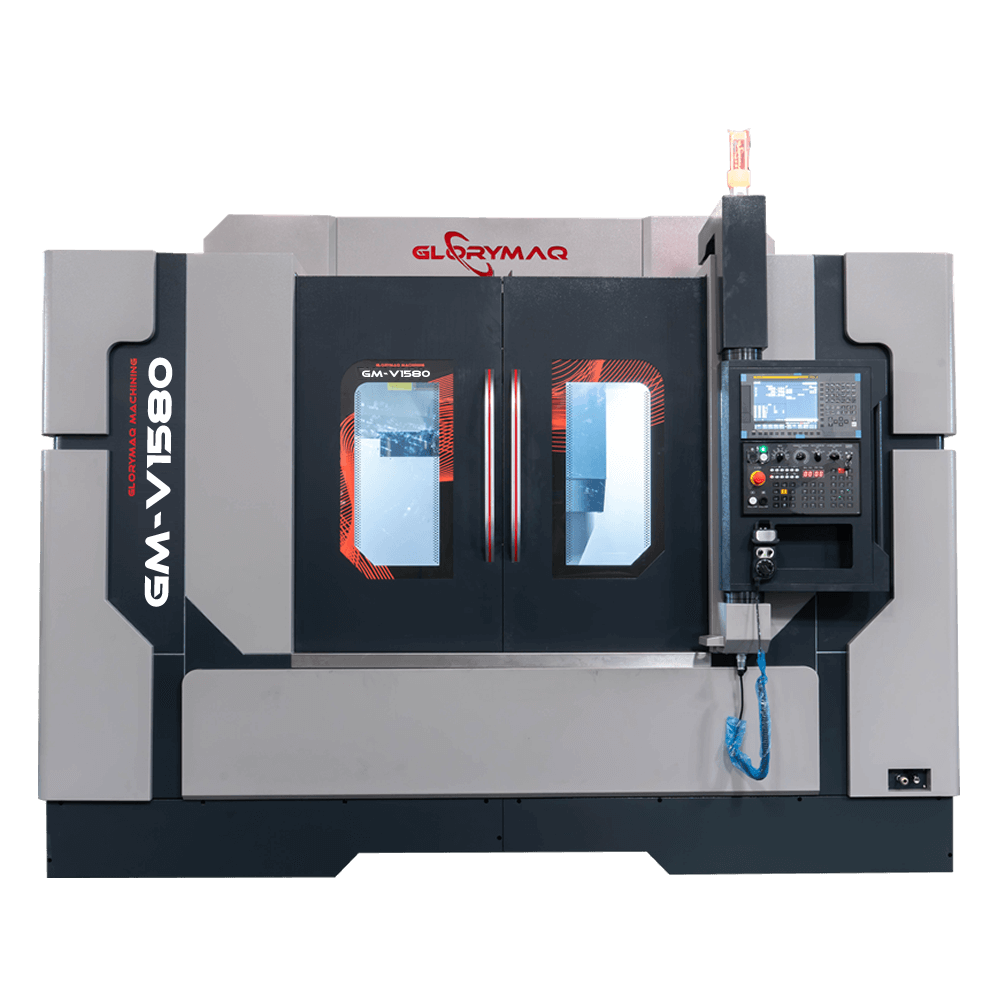

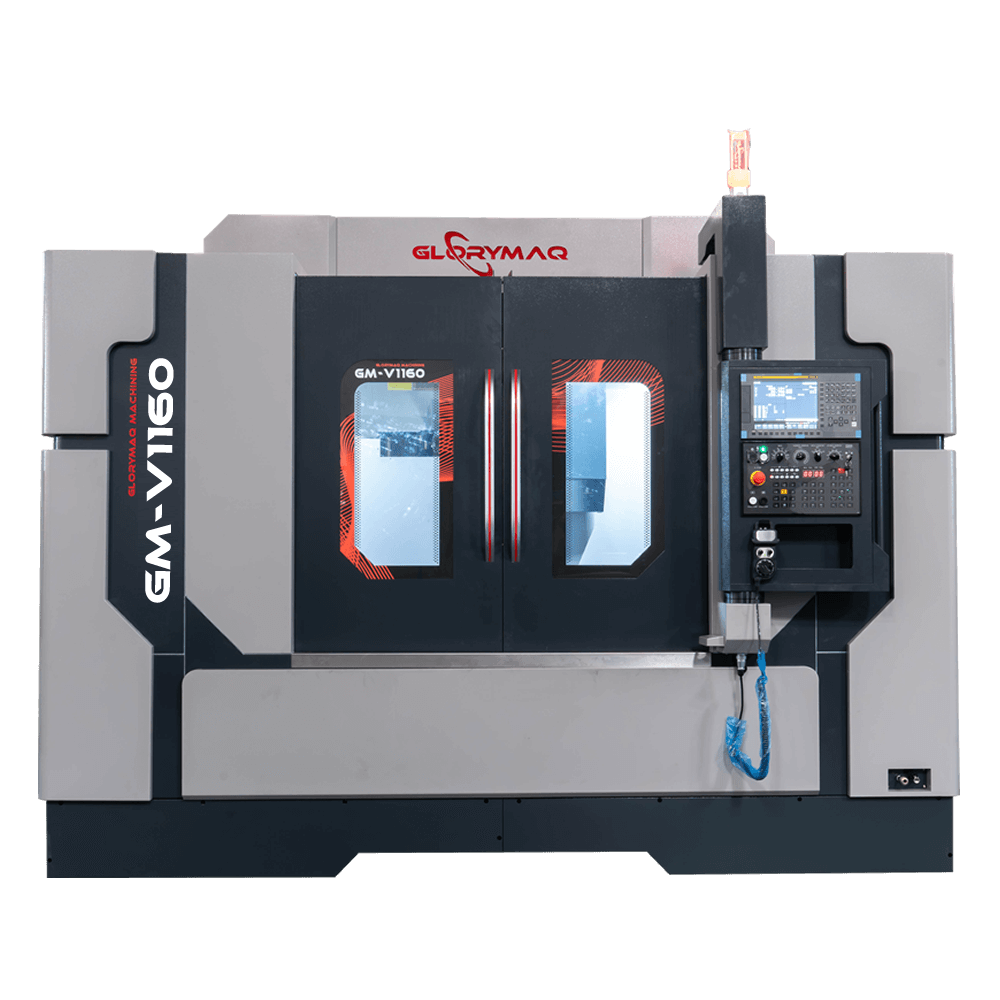

GM-L1580 Vertical Machining Center

VMC-L1580 Vertical Machining Center High-speed tool changing mechanism design, using hunch should control, combined with efficient tool changing system, to achieve tool changing work, tool changing speed, to achieve high-speed tool changing function.The operation interface is simple, intuitive and easy to operate, and it can realize automatic processing through pre-written programs to improve production efficiency. Z-axis with hard rails provides higher vertical stability and better rigidity, resulting in higher machining accuracy and surface quality.

Classification:

Key words:

Vertical Machining Center

cnc vertical machining center for sale

new vertical machining center

VMC-L1580

Detail description

VMC-L1580 Vertical Machining Center base adopts A-rib structure to improve the effect of vibration absorption, and the whole casting adopts box design with high bending stiffness.

The frame is made of high quality Mihanyue cast iron, which is tempered to eliminate internal stress and ensure optimum rigidity, accuracy and durability.

Years of experience data accumulation and rationalization of mechanism slenderness ratio design to improve the compressive strength and lateral bending strength of castings resulted in the high stiffness structure.

VMC-L1580 Vertical Machining Center High-speed tool changing mechanism design, using hunch should control, combined with efficient tool changing system, to achieve tool changing work, tool changing speed, to achieve high-speed tool changing function.

cnc vertical machining center for sale:market001@glorymaq.com Get Nice Factory Price

| Technical specification | ||

| MODEL | GM-L1580 | |

| Axis travel | ||

| X,Y,Z axes | mm | 1500*800*700 |

| Distance from spindle center line to column | mm | 810 |

| Distance from spindle nose to worktable | mm | 130-830 |

| Table | ||

| Table size | mm | 1700*800 |

| T slot | mm | 22T*5*135 |

| Table load capacity | kg | 1500 |

| Coupling | ||

| Spindle taper hole | BT | BT50 |

| Optional speed* | rpm | 6000/8000(Optional)* |

| Spindle power | kw | 18.5 |

| Spindle connection mode | Belt drive | |

| Three-axis connection mode | Direcet drive | |

| Three axis motor power | kw | 4.5/4.5/4.5 |

| Linear guide and ball screw (PMI/HIWIN/HSK) | ||

| Linear guide (X/Y /), Z "box guide" | mm | 55/45 (Y:4 Linear) |

| Ball screw (X / Y / Z) | mm | 50*10 |

| Max.Rapid traverse ( X / Y / Z) (Use of this extreme parameter for prolonged durations is not advisable.) | m/min | 20/20/12 |

| Accuracy | ||

| Positioning accuracy | mm | ±0.008/300 |

| Repeated positioning accuracy | mm | ±0.008/300 |

| Tool changing device (automatic) | ||

| Tool capacity | un | 24 |

| max tool weight | kg | 15 |

| max tool length | mm | 330 |

| max tool diameter(full tool/adjacent empty tool) | mm | 200 |

| tool magazine form | BT50 | |

| Optional * | ||

| System | SIEMENS-828D / MITSUBISHI-M80B / Fanuc Oi-MF Plus | |

| Chip conveyor | Optional * | |

| 4 axis | Optional * | |

| Spindle center water outlet | Optional * | |

| Automatic tool measurement function | Optional * | |

| Other | ||

| Size | mm | 4000*3240*3100 |

| Evaluated machine weight including accessories | kg | 9600 |

Refer to Power Requirements

| Power correspondence table |

55~90A |

220V |

60Hz |

3Φ |

25kW |

Refer to Pressure Requirements

| Pressure source pressure | Set pressure | Ambient temperature | Relative humidity | Air supply |

|

5~7bar |

5bar |

0~45℃ |

<90%RH |

380l/min |

5G COMMUNICATION

NEW ENERGY VEHICLE

A SHIP

AEROSPACE

3C ELECTRONICS

PRECISION DIE

Dongguan Glorymaq Technology Co., LTD focuses on the two core business segments of "advanced intelligent equipment" and "intelligent manufacturing services". The company's main products are: drilling and milling machining centers, vertical machining centers, horizontal machining centers, gantry machining centers, profile machining centers, CNC lathes, centering machines, precision carving machining centers, five axis machining centers and other machine tools.

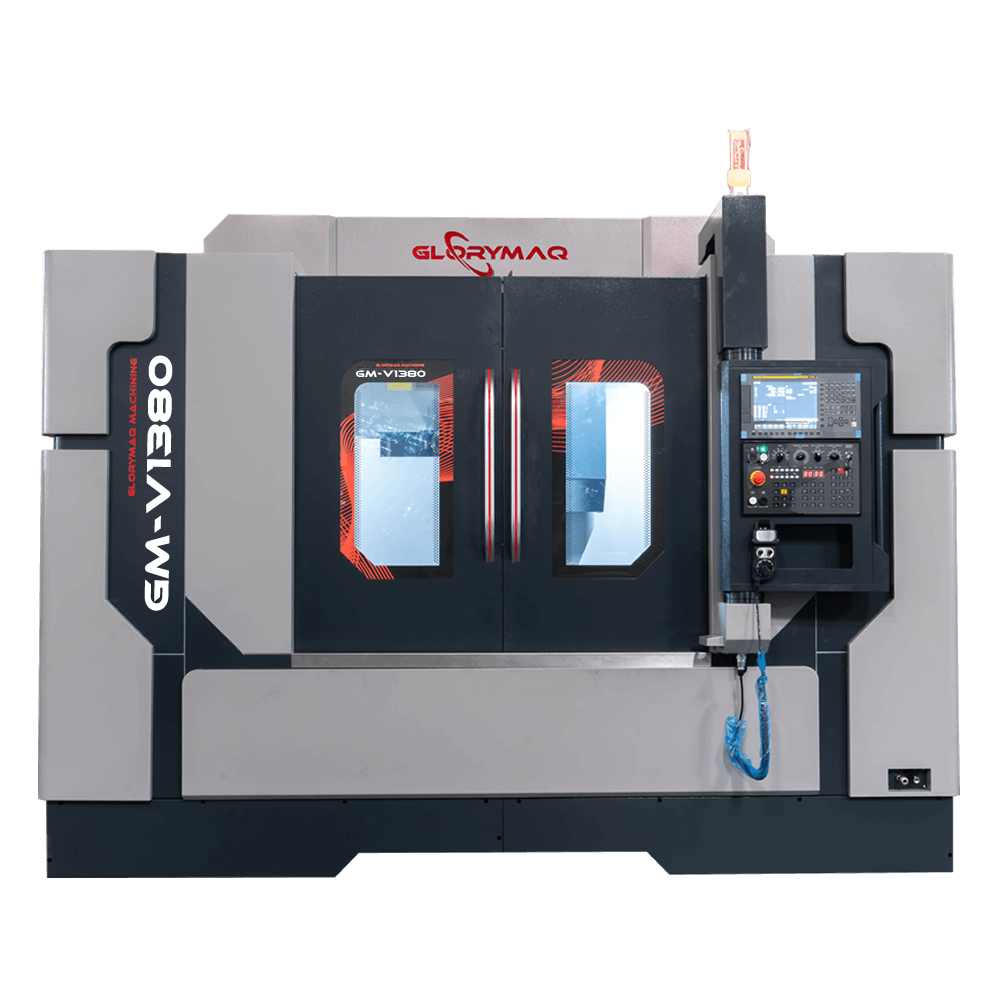

Related products

Advisory message