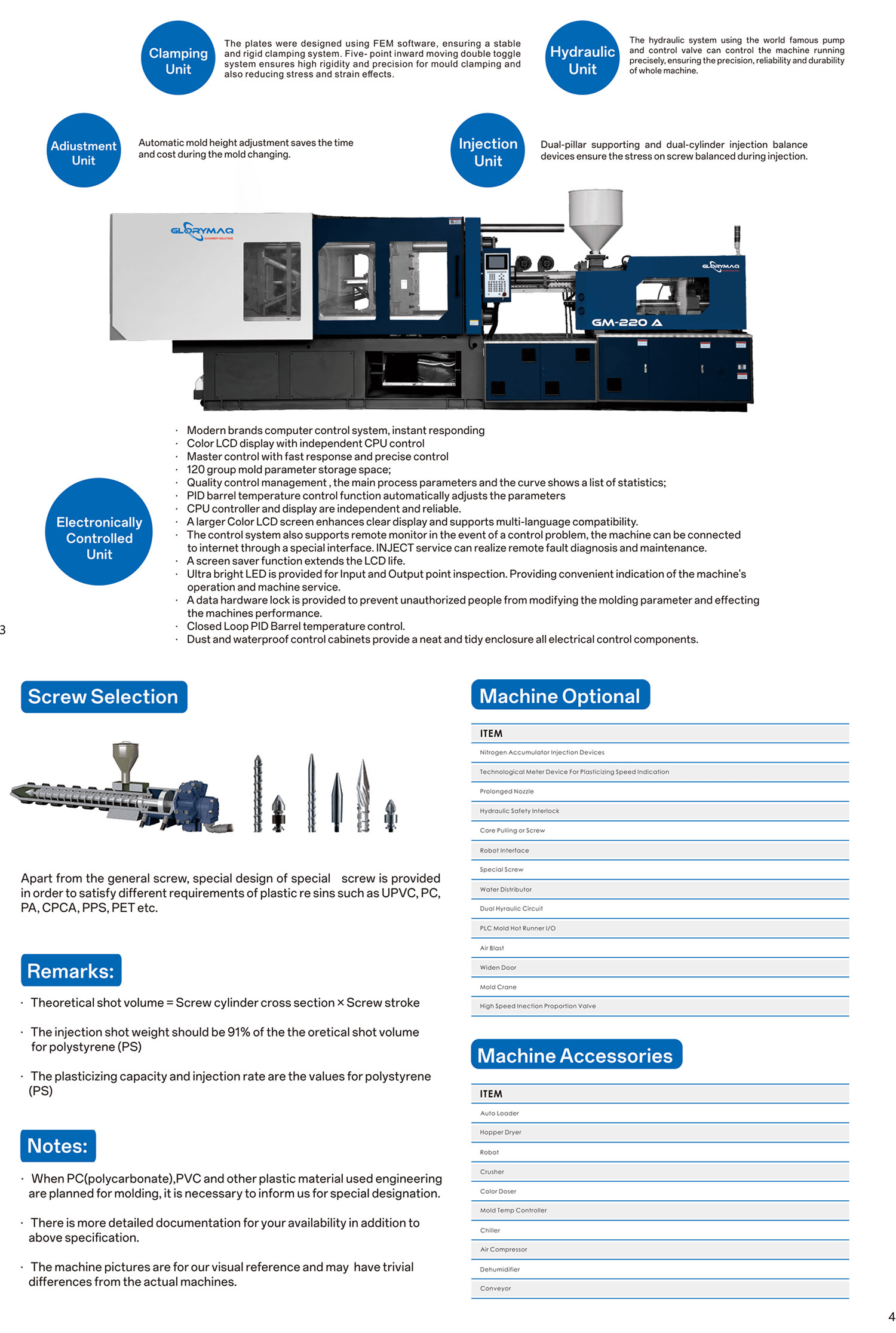

GM-DC series Injection Molding Machine

Discover energy-efficient industrial injection molding machines suitable for medical, automotive, home appliance industries, enjoy customized services and professional after-sales support, enhance production efficiency, reduce energy costs, and embark on a new era of intelligent injection molding.

Classification:

Key words:

Industrial Injection Molding Machine

Injection Molding Machine

Detail description

Discover energy-efficient industrial injection molding machines suitable for medical, automotive, home appliance industries, enjoy customized services and professional after-sales support, enhance production efficiency, reduce energy costs, and embark on a new era of intelligent injection molding.

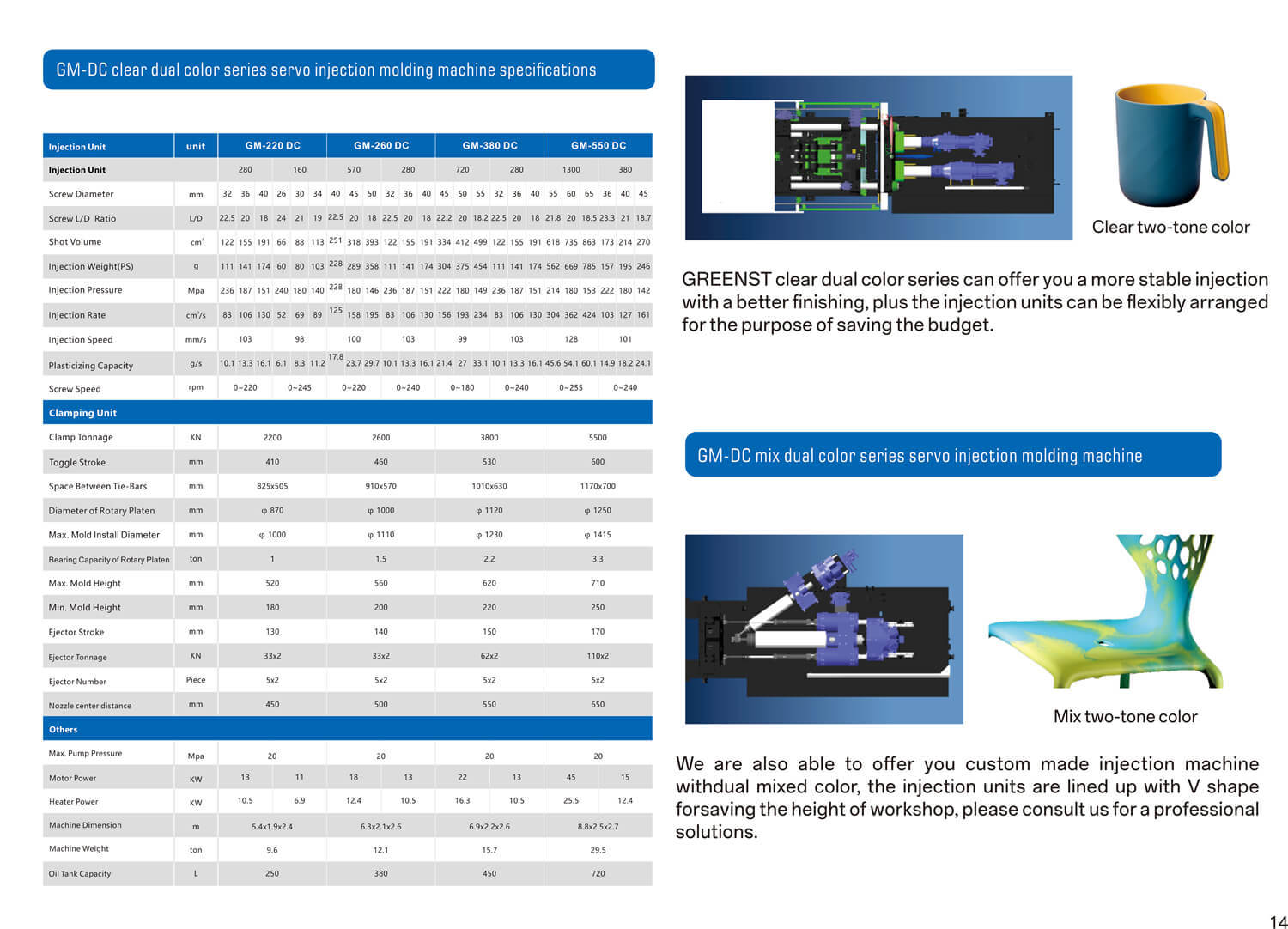

| lnjection Unit | unit | GM-220 DC | GM-260 DC | GM-380 DC | GM-550 DC | ||||||||||||||||||||

| lnjection Unit | 280 | 160 | 570 | 280 | 720 | 280 | 1300 | 380 | |||||||||||||||||

| Screw Diameter | mm | 32 | 36 | 40 | 26 | 30 | 34 | 40 | 45 | 50 | 32 | 36 | 40 | 45 | 50 | 55 | 32 | 36 | 40 | 55 | 60 | 65 | 36 | 40 | 45 |

| Screw L/D Ratio | L/D | 22.5 | 20 | 18 | 24 | 21 | 19 | 22.5 | 20 | 18 | 22.5 | 20 | 18 | 22.2 | 20 | 18.2 | 22.5 | 20 | 18 | 21.8 | 20 | 18.5 | 23.3 | 21 | 18.7 |

| Shot volume | cm³ | 122 | 155 | 191 | 66 | 88 | 113 | 251 | 318 | 393 | 122 | 155 | 191 | 334 | 412 | 499 | 122 | 155 | 191 | 618 | 735 | 863 | 173 | 214 | 270 |

| lnjection Weight(PS) | g | 111 | 141 | 174 | 60 | 80 | 103 | 228 | 289 | 358 | 111 | 141 | 174 | 304 | 375 | 454 | 111 | 141 | 174 | 562 | 669 | 785 | 157 | 195 | 246 |

| lnjection Pressure | Mpa | 236 | 187 | 151 | 240 | 180 | 140 | 228 | 180 | 146 | 236 | 187 | 151 | 222 | 180 | 149 | 236 | 187 | 151 | 214 | 180 | 153 | 222 | 180 | 142 |

| lnjection Rate | cm³/s | 83 | 106 | 130 | 52 | 69 | 89 | 125 | 158 | 195 | 83 | 106 | 130 | 156 | 193 | 234 | 83 | 106 | 130 | 304 | 362 | 424 | 103 | 127 | 161 |

| lnjection Speed | mm/s | 103 | 98 | 100 | 103 | 99 | 103 | 128 | 101 | ||||||||||||||||

| Plasticizing Capacity | g/s | 10.1 | 13.3 | 16.1 | 6.1 | 8.3 | 11.2 | 17.8 | 23.7 | 29.7 | 10.1 | 13.3 | 16.1 | 21.4 | 27 | 33.1 | 10.1 | 13.3 | 16.1 | 45.6 | 54.1 | 60.1 | 14.9 | 18.2 | 24.1 |

| Screw Speed | rpm | 0-220 | 0-245 | 0-220 | 0-240 | 0-180 | 0-240 | 0-255 | 0-240 | ||||||||||||||||

| Clamping Unit | |||||||||||||||||||||||||

| Clamp Tonnage | KN | 2200 | 2600 | 3800 | 5500 | ||||||||||||||||||||

| Toggle Stroke | mm | 410 | 460 | 530 | 600 | ||||||||||||||||||||

| Space Between Tie-Bars | mm | 825x505 | 910x570 | 1010x630 | 1170x700 | ||||||||||||||||||||

| Diameter of Rotary Platen | mm | φ 870 | φ 1000 | φ 1120 | φ 1250 | ||||||||||||||||||||

| Max. Mold lnstall Diameter | mm | φ 1000 | φ 1110 | φ 1230 | φ 1415 | ||||||||||||||||||||

| Bearing Capacity of Rotary Platen | ton | 1 | 1.5 | 2.2 | 3.3 | ||||||||||||||||||||

| Max.Mold Height | mm | 520 | 560 | 620 | 710 | ||||||||||||||||||||

| Min.Mold Height | mm | 180 | 200 | 220 | 250 | ||||||||||||||||||||

| Ejector Stroke | mm | 130 | 140 | 150 | 170 | ||||||||||||||||||||

| Ejector Tonnage | KN | 33x2 | 33x2 | 62x2 | 110x2 | ||||||||||||||||||||

| Ejector Number | Piece | 5x2 | 5x2 | 5x2 | 5x2 | ||||||||||||||||||||

| Nozzle center distance | mm | 450 | 500 | 550 | 650 | ||||||||||||||||||||

| Others | |||||||||||||||||||||||||

| Max.Pump Pressure | Mpa | 20 | 20 | 20 | 20 | ||||||||||||||||||||

| Motor Power | KW | 13 | 11 | 18 | 13 | 22 | 13 | 45 | 15 | ||||||||||||||||

| Heater Power | KW | 10.5 | 6.9 | 12.4 | 10.5 | 16.3 | 10.5 | 25.5 | 12.4 | ||||||||||||||||

| Machine Dimension | m | 5.4x1.9x2.4 | 6.3x2.1x2.6 | 6.9x2.2x2.6 | 8.8x2.5x2.7 | ||||||||||||||||||||

| Machine Weight | ton | 9.6 | 12.1 | 15.7 | 29.5 | ||||||||||||||||||||

| Oil Tank Capacity | L | 250 | 380 | 450 | 720 | ||||||||||||||||||||

Energy-Efficient: Leveraging state-of-the-art servo energy-saving technology, this system achieves precise regulation of pressure and flow, resulting in energy savings ranging from 20% to 80%. This significantly mitigates production costs.

High-Precision Production: Equipped with high-performance servo controllers and motors, the system markedly enhances repeatability, thereby ensuring product precision and consistency.

Wide Application: Applicable across a broad spectrum of industries such as medical, automotive, home appliances, packaging, and electronics, this solution meets diverse production requirements.

Intelligent Operation: The intelligent control system streamlines operational procedures, thereby enhancing production efficiency and minimizing human errors.

Eco-Friendly Design: Emphasizing environmental protection and energy conservation, this design employs green manufacturing technologies to reduce energy consumption and waste emissions, aligning with contemporary eco-friendly standards.

Customized Service: Tailored customization solutions are provided based on specific customer needs, addressing unique production requirements.

Comprehensive After-Sales Service: A full suite of pre-sales, mid-sales, and after-sales services is offered to ensure customers' peace of mind and optimal use of the product.

Get in Touch Now: Obtain more product information and customized solutions to make your production more efficient, precise, and eco-friendly. market001@glorymaq.com

Choose our injection molding machine to make your production more efficient, precise, and eco-friendly, and usher in a new era of intelligent injection molding.

5G COMMUNICATION

NEW ENERGY VEHICLE

A SHIP

AEROSPACE

3C ELECTRONICS

PRECISION DIE

Dongguan Glorymaq Technology Co., LTD focuses on the two core business segments of "advanced intelligent equipment" and "intelligent manufacturing services". The company's main products are: drilling and milling machining centers, vertical machining centers, horizontal machining centers, gantry machining centers, profile machining centers, CNC lathes, centering machines, precision carving machining centers, five axis machining centers and other machine tools.

Prev

Prev

Related products

Advisory message