GM-61100B Universal Lathe Machine

Multi-functional Flexibility: As an indispensable all-rounder in the manufacturing workshop, the Universal Lathe integrates multiple functions including turning, boring, drilling, tapping, and more into a single machine.

Classification:

Key words:

Universal Lathe machine price

GM-61100B

Detail description

| Technical Specification | ||||||

| Item | Unit | GM-61100B | ||||

| Maximum turning diameter | mm | Φ1000 | ||||

| Maximum turning diameter on board | mm | Φ680 | ||||

| Distance from top to tip | mm | 1000/1500/2000/3000 | ||||

| Maximum cutting length | mm | 850/1350/1850/2850 | ||||

| Maximum cutting diameter | Plate type | mm | Φ1000 | |||

| Axis type | mm | Φ660 | ||||

| Spindle end and through-hole diameter | mm | C-11/ Φ100 | ||||

| Maximum bar diameter through spindle | mm | Φ85 | ||||

| hydraulic chuck | / | 15´´ | ||||

| Tail seat center sleeve diameter | mm | MT5/Φ100 | ||||

| Center sleeve travel | mm | 250 | ||||

| Spindle speed range | r/min Low | 40-125 | ||||

| r/min Middle | 110-350 | |||||

| r/min High | 290-950 | |||||

| Spindle speed series | Mechanical 3rd gear,no limit within the gear | |||||

| Guideway width | mm | 600 | ||||

| X/Z-axis speed | m/min | 4/6 | ||||

| X-axis travel | mm | 560 | ||||

| Z-axis travel | mm | 1000/1500/2000/3000 | ||||

| Tool size | Cylindrical cutter | mm | 32×32 | |||

| Boring tool | mm | Φ32 | ||||

| Maximum load | Plate type | kg | 800 | |||

| Axis type | kg | 2500 | ||||

| Center height(To lathe foot surface) | mm | * | ||||

| Roundness of the workpiece | mm | 0.008/Ф75 | ||||

| Cylindricity of the workpiece | mm | 0.03/300 | ||||

| Flatness of the workpiece | mm | 0.025/300 | ||||

| Roughness of the workpiece | / | Ra1.6μm | ||||

| X/Z Repeated positioning accuracy | mm | 0.011/0.03 | ||||

| Optional configuration | CNC control system | / | fanuc,Mitsubishi, Siemens, Snytec , GSK-980 | |||

| Tool holder type (Optional) | / | 4 station/6 station/8 station | ||||

| Main power | Voltage/Frequency | V/HZ | AC380/50HZ/60HZ | |||

| Main power capacity | KVA | 35 | ||||

| Machine weight | kg | 5200/5600/6000/6500 | ||||

| Machine dimension | Length | mm | 3300/3800/4300/5300 | |||

| Length X Width X height | mm | 2250*1980 | ||||

Refer to Power Requirements

| Power correspondence table |

55~90A |

220V |

60Hz |

3Φ |

25kW |

Refer to Pressure Requirements

| Pressure source pressure | Set pressure | Ambient temperature | Relative humidity | Air supply |

|

5~7bar |

5bar |

0~45℃ |

<90%RH |

380l/min |

Universal Lathe machine price list:market001@glorymaq.com

Universal Lathe: Your Versatile Manufacturing Partner

1. Multi-functional Flexibility: As an indispensable all-rounder in the manufacturing workshop, the Universal Lathe integrates multiple functions including turning, boring, drilling, tapping, and more into a single machine. This versatile equipment is capable of handling a wide array of complex workpieces and meeting diverse production requirements with ease.

2. Precision Craftsmanship: Featuring precision lead screws and guideway systems, the lathe ensures each cut achieves micron-level accuracy. It maintains exceptional quality standards for both high-precision tasks and large-scale standardized production processes.

3. Extensive Compatibility: The Universal Lathe offers broad compatibility with various tools and attachments, ranging from standard cutters to specialized customizations. This adaptability caters to comprehensive processing needs, from simple to complex components and small to large parts.

4. User-friendly Operation: The lathe is equipped with an intuitive control panel and user-friendly interface, enabling even novice operators to quickly become proficient. Additionally, safety features are integrated to ensure both operational safety and efficiency.

5. High Efficiency and Energy Savings: Utilizing advanced drive technology and energy-efficient designs, the lathe enhances processing efficiency while significantly reducing energy consumption. This delivers substantial economic benefits and environmental value to your production operations.

6. Robust Durability: Constructed from premium materials and manufactured with meticulous craftsmanship, the main body of the lathe remains resilient and maintains high precision and stability during prolonged intensive operation, serving as a reliable long-term partner.

Choose our Universal Lathe to embark on a journey towards efficient, flexible, and precise manufacturing solutions, elevating your production capabilities and co-creating a brilliant future!

5G COMMUNICATION

NEW ENERGY VEHICLE

A SHIP

AEROSPACE

3C ELECTRONICS

PRECISION DIE

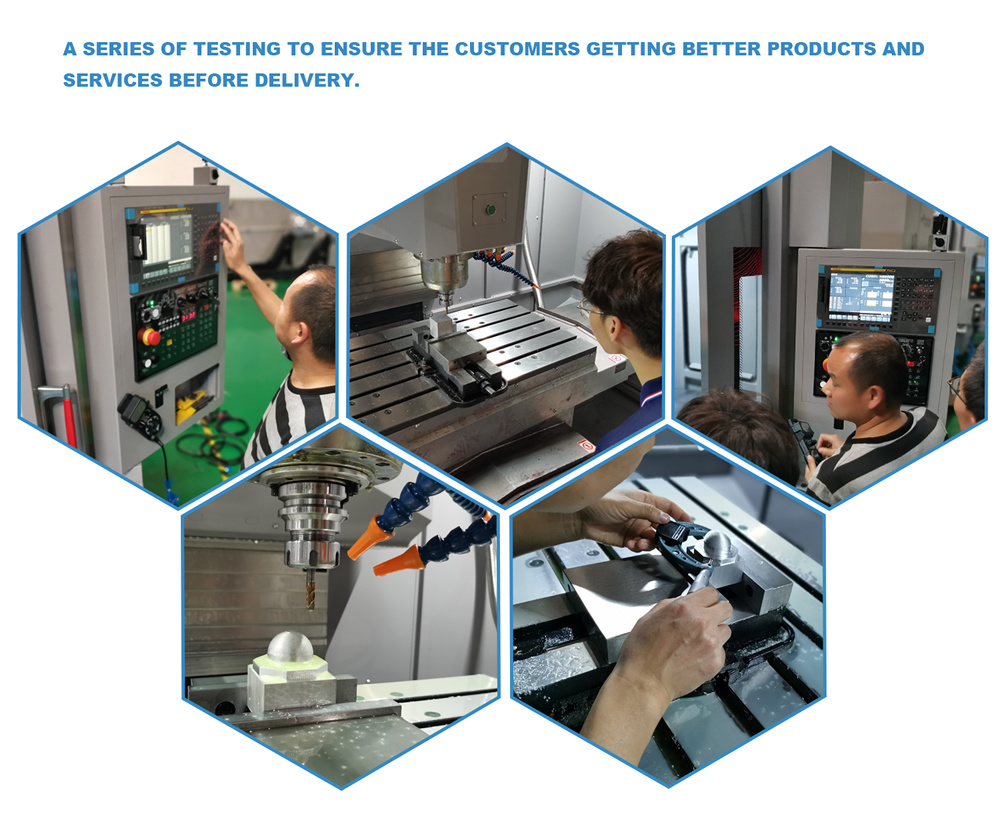

Dongguan Glorymaq Technology Co., LTD focuses on the two core business segments of "advanced intelligent equipment" and "intelligent manufacturing services". The company's main products are: drilling and milling machining centers, vertical machining centers, horizontal machining centers, gantry machining centers, profile machining centers, CNC lathes, centering machines, precision carving machining centers, five axis machining centers and other machine tools.

Prev

Prev

Related products

Advisory message