GM-46T Turning center "Turret with live tools”cnc lathe machine

CNC Lathe machine tool adopts mechanical and electrical integration design, the overall layout is compact and reasonable, convenient and pleasant operation, easy maintenance.

Classification:

Key words:

CNC Lathe

china cnc turning machine

cnc lathe machine

CNC turning lathe

Detail description

CNC Lathe turning center is designed and developed for complex and high precision parts. It has the advantages of compact structure, powerful function, high machining precision positioning and preservation technology. Spindle is equipped with servo motor, repeated positioning accuracy ±0.008mm. Suitable power tools can be used for complex machining, engraving, drilling and threading, open software interface, accept standard g codes and a variety of CAM software input processing instructions.

1, the structure design of strong pertinency, mainly used for disk class, shaft class, set of class processing.

2. High rigidity, small thermal deformation, low temperature rise of the main shaft, small vibration, large cutting torque, can adapt to strong cutting.

3, the spindle adopts three-point structure, stable transmission and strength can realize a variety of grooving, drilling, reaming, reaming and boring processing.

4, the key CNC system of machine tool, spindle bearing, ball screw and other famous brands at home and abroad, so that the machine tool has high reliability.

5, CNC Lathe machine tool processing workpiece consistency is good

6, Adopt modular design, can provide a variety of configurations according to user requirements.

7, CNC Lathe machine tool adopts mechanical and electrical integration design, the overall layout is compact and reasonable, convenient and pleasant operation, easy maintenance.

china cnc turning center lathe manufacturers:market001@glorymaq.com Get Nice Factory Price

| Technical specification | ||

| MODEL | GM-46T | |

| Coupling | ||

| Spindle head shape | mm | A2-5 |

| Spindle hole diameter | mm | 56 |

| Maximum bar diameter(passage) | mm | 45 |

| Chuck | inch | 6/8 |

| Maximum speed | rpm | 4000 |

| Allowable diameter | ||

| Maximum swing diameter over bed | mm | 500 |

| Maximum turning diameter | mm | 480 |

| Maximum machining length | mm | 520 |

| X-axis travel | mm | 200 |

| Z-axis travel | mm | 560 |

| Y-axis travel | mm | * |

| Feed Rate | ||

| Rapid traverse (X-axis) | m/min | 25 |

| Rapid traverse (Z-axis) | m/min | 25 |

| Tool holder | ||

| tool holder shape | * | Servo Turret 12T |

| power-head power | kw | * |

| spindle motor | kw | 7.5 |

| Spindle connection mode | Belt drive | |

| X/Z Axis connection mode | Direct drive | |

| X/Z Axis motor power | kw | 1.8/1.8 |

| External tool holder (section) | mm | 25 |

| Internal tool holder (diameter) | mm | 32 |

| Tailstock | ||

| Tailstock quill taper | * | MT-5 |

| Travel | mm | 100 |

| Accuracy | ||

| Positioning accuracy | mm | ±0.008/300 |

| Repeated positioning accuracy | mm | ±0.008/300 |

| Optional * | ||

| System | SIEMENS-828D / Fanuc Oi-TF Plus / Syntec / | |

| Chip removal machine | Optional * | |

| Automatic tool measurement function | Optional * | |

| Other | ||

| Evaluated machine weight including accessories | kg | 3600 |

| Machine size | mm | 2800*1800*1820 |

Refer to Power Requirements

| Power correspondence table |

55~90A |

220V |

60Hz |

3Φ |

25kW |

Refer to Pressure Requirements

| Pressure source pressure | Set pressure | Ambient temperature | Relative humidity | Air supply |

|

5~7bar |

5bar |

0~45℃ |

<90%RH |

380l/min |

5G COMMUNICATION

NEW ENERGY VEHICLE

A SHIP

AEROSPACE

3C ELECTRONICS

PRECISION DIE

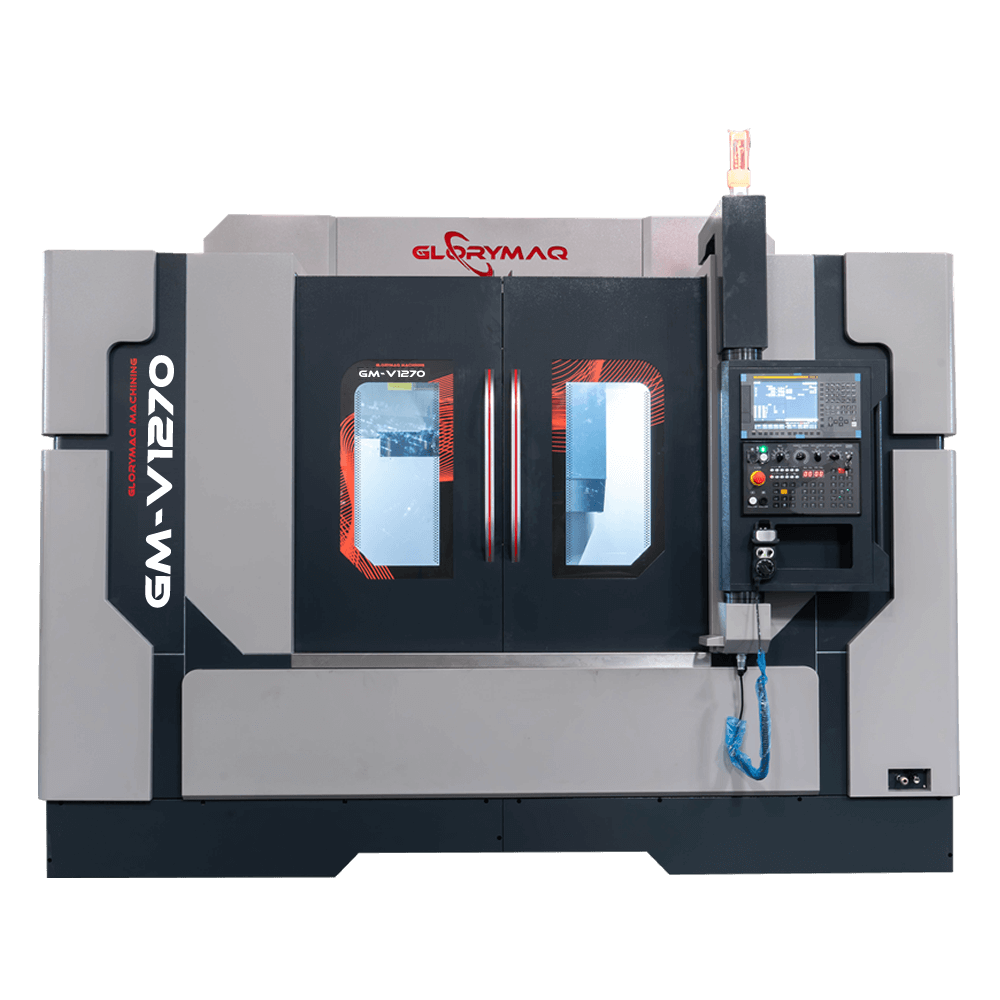

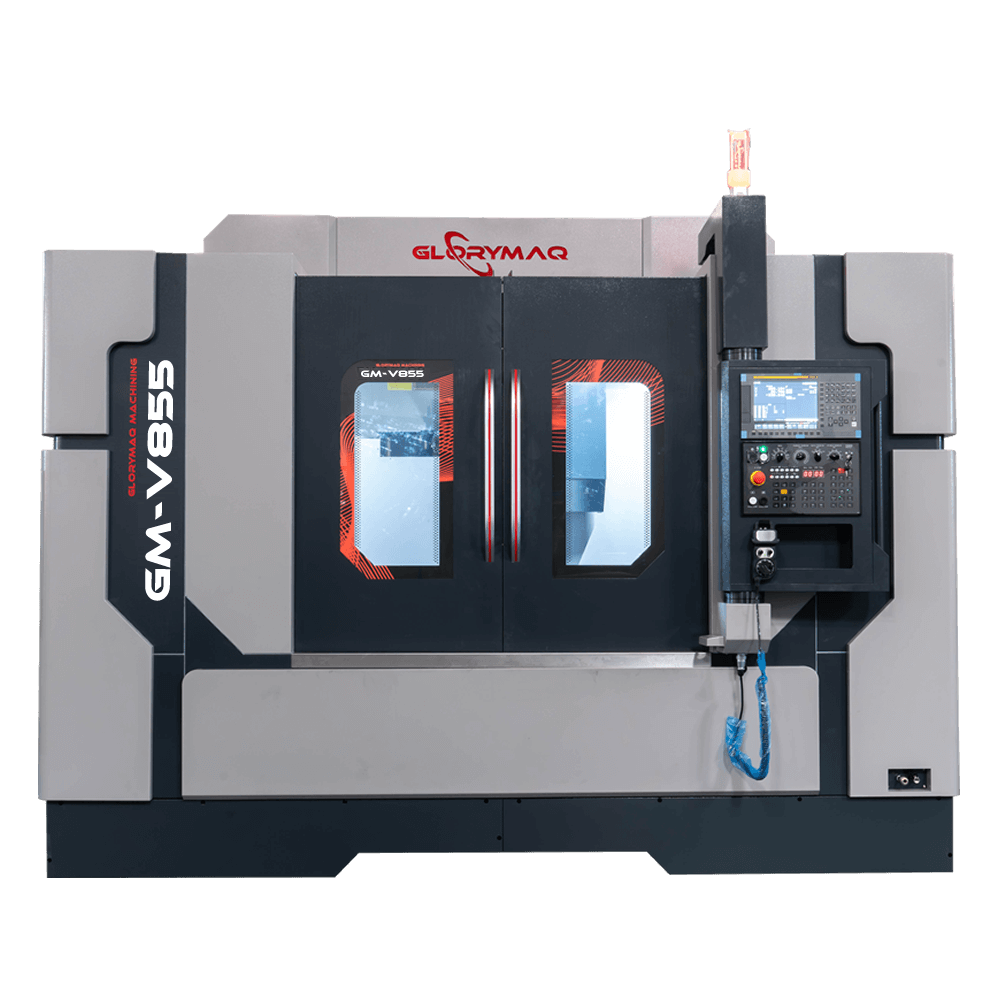

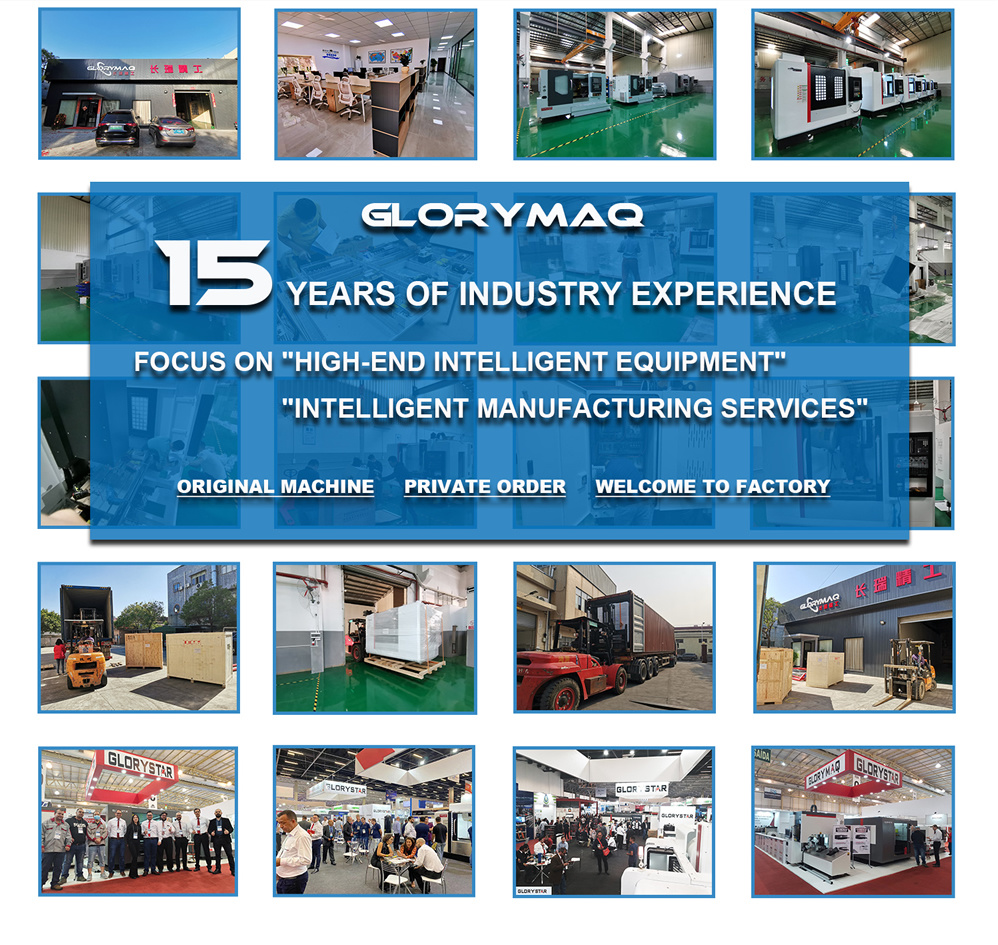

Dongguan Glorymaq Technology Co., LTD focuses on the two core business segments of "advanced intelligent equipment" and "intelligent manufacturing services". The company's main products are: drilling and milling machining centers, vertical machining centers, horizontal machining centers, gantry machining centers, profile machining centers, CNC lathes, centering machines, precision carving machining centers, five axis machining centers and other machine tools.

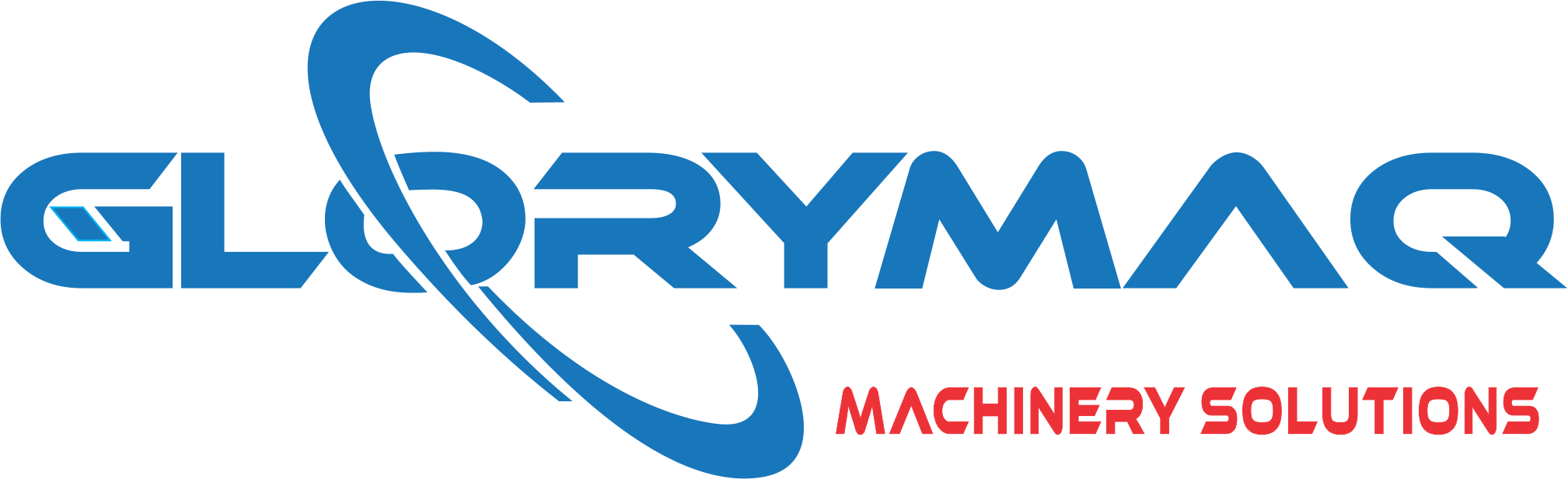

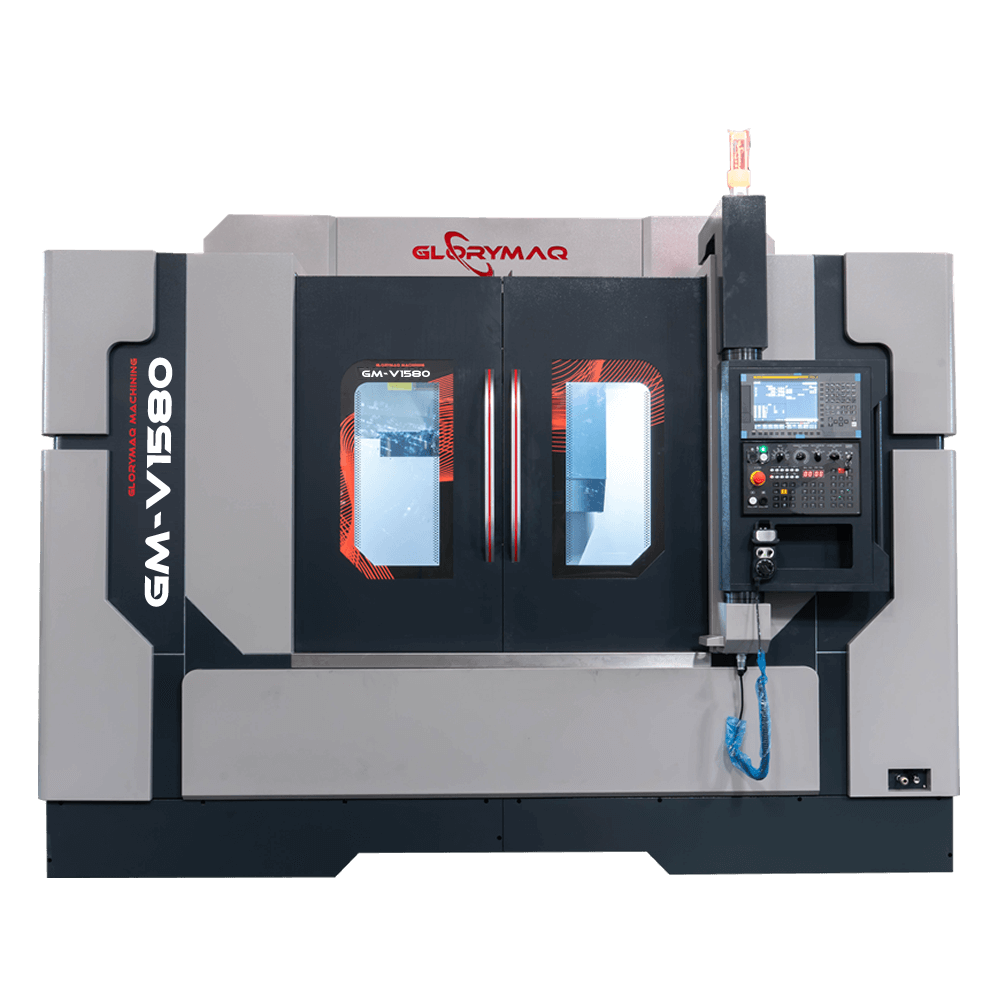

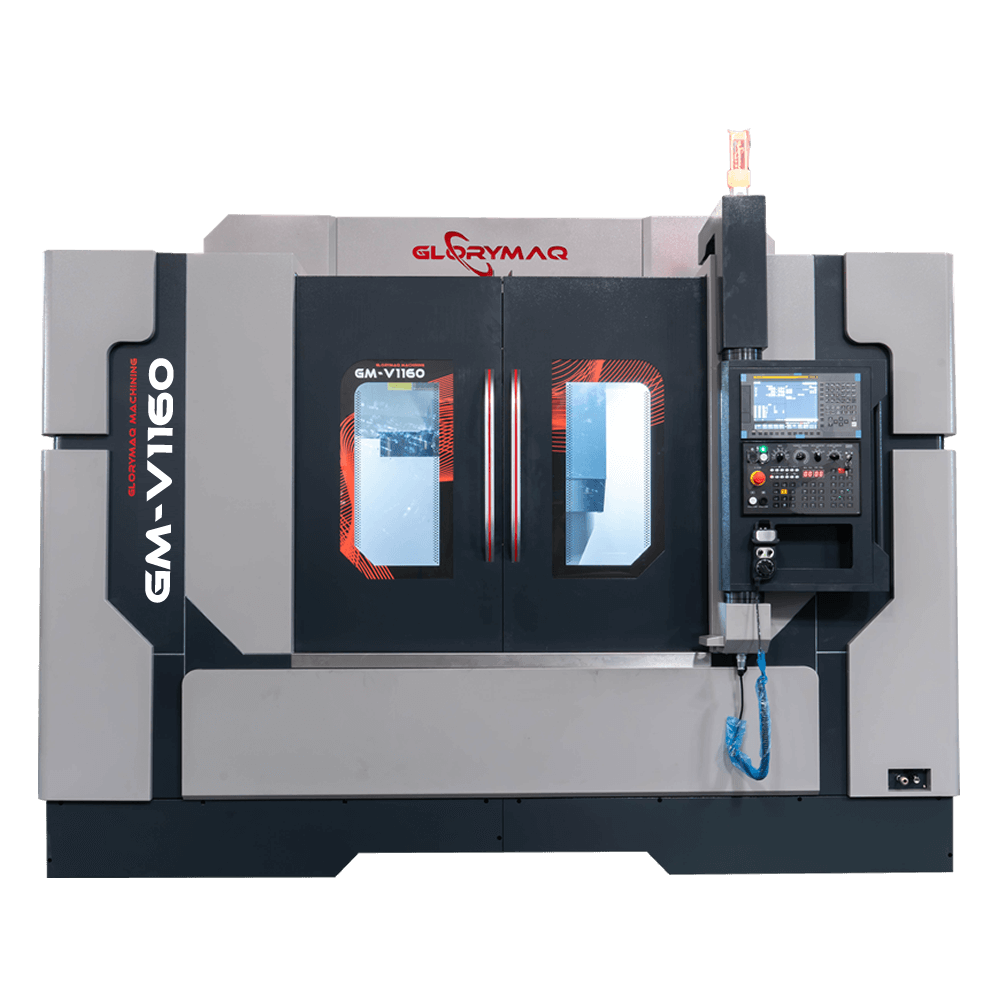

Related products

Advisory message