17

2025

-

03

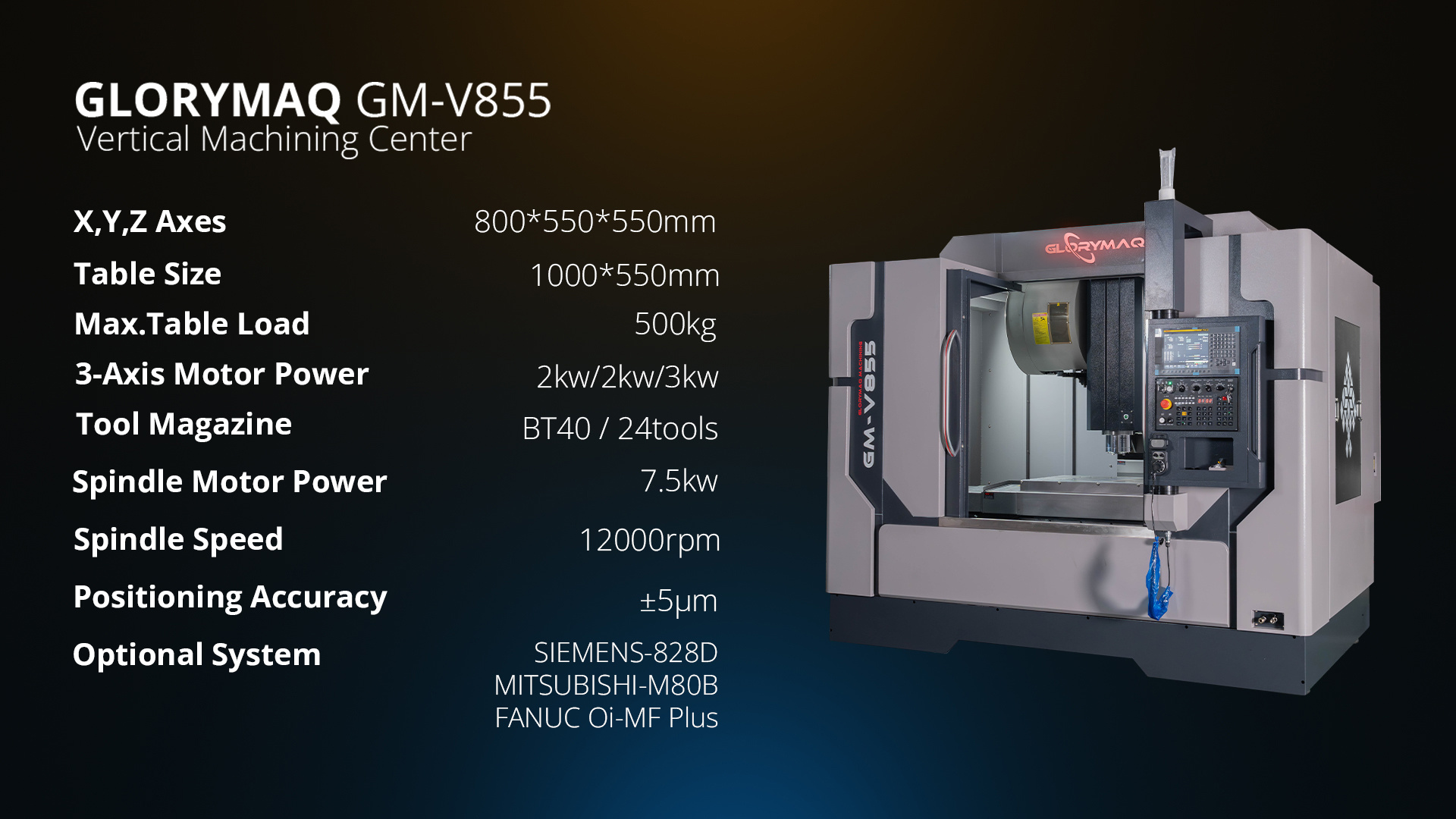

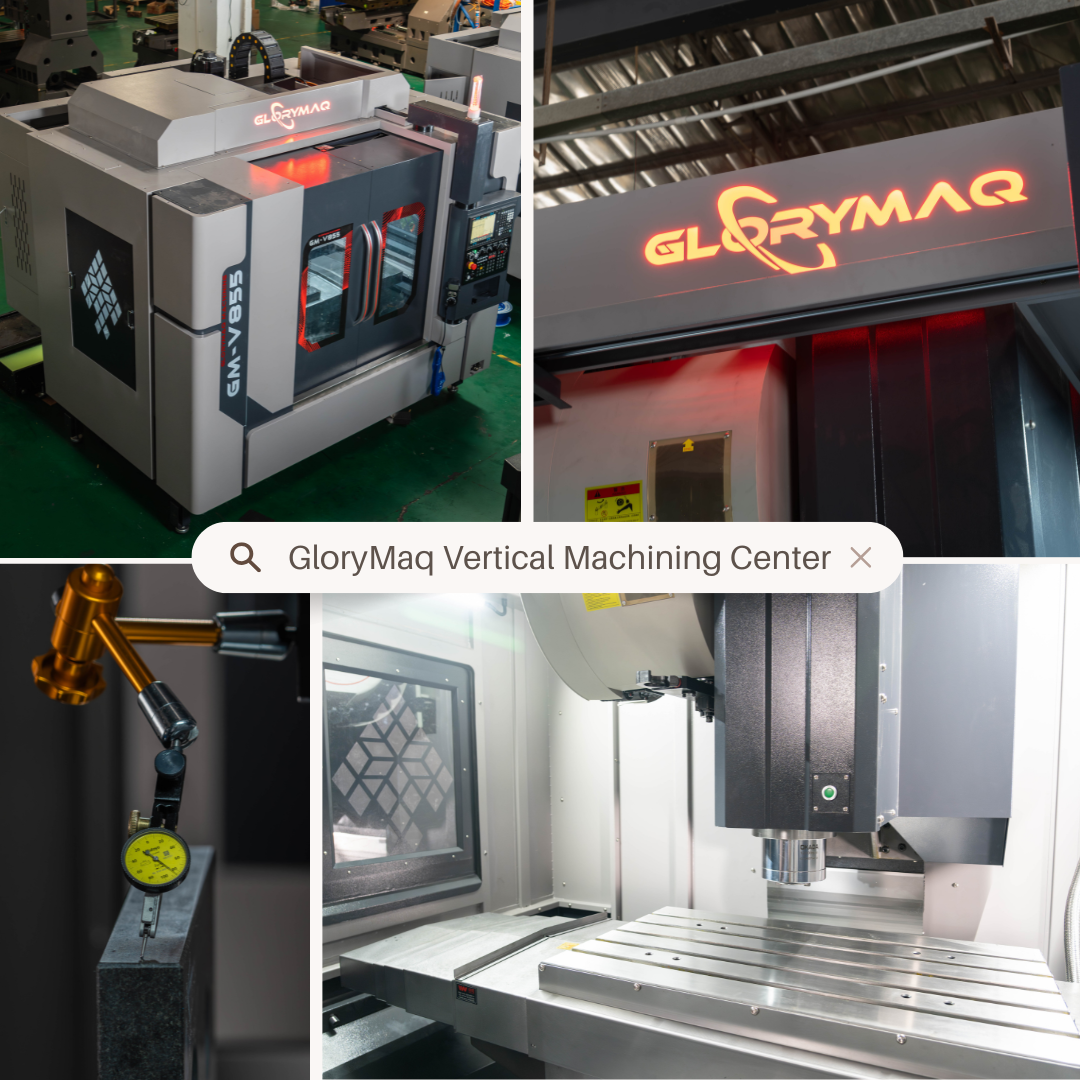

Glorymaq V855 CNC Vertical Machining Center: Precision, Profitability, and Peace of Mind

Classification:

【News Summary】Glorymaq V855 CNC Vertical Machining Center: Precision, Profitability, and Peace of Mind

Core Machine Architecture

Model:GM-V855

Design Philosophy:Balancing rigidity, speed, and precision for aerospace, automotive, and mold/die industries.

| Category | Specification |

|---|---|

| Axis Travel (X/Y/Z) | 800×550×550 mm |

| Spindle Positioning | 590 mm (Column to spindle center) / 120-670 mm (Spindle nose to table) |

| Worktable | 1000×550 mm, 500 kg max load, 18T×5×90 mm T-slots |

| Linear Motion System | PMI/HIWIN/HSK linear guides (X:35mm / Y/Z:45mm) + 40×12mm ball screws |

Key Performance Highlights

1. High-Speed Precision Machining

-

Spindle Options:

-

Standard: 10,000/12,000 RPM (BT40 taper, 7.5kW motor)

-

Drive Flexibility: Belt drive for torque-intensive jobs / Direct drive for high-speed finishing

-

-

Rapid Traverse: 48 m/min (X/Y/Z) – Ideal for thin-walled aerospace components and rapid prototyping.

-

Accuracy:

-

Positioning: ±0.005/300mm (ISO 10791-1 compliant)

-

Repeatability: ±0.005/300mm

-

2. Mission-Ready Tool Management

-

24-Tool Automatic Magazine:

-

Max tool weight: 15 kg

-

Max tool length: 300 mm

-

Tool diameter: 200 mm (full tool) / Adjacent tool clearance optimized

-

-

Optional Upgrades:

-

Automatic tool measurement (laser/contact probe)

-

4th axis rotary table for complex contours

-

3. Industrial-Grade Structural Integrity

-

Cast Iron Bed: Vibration-damped design with 5,100 kg total weight ensures stability during heavy cutting.

-

Direct-Drive Motors: X/Y/Z axes powered by 2/2/3 kW motors for high torque and minimal backlash.

Smart Configuration Options

Tailor the V855 to Your Production Needs:

| Option | Technical Benefits |

|---|---|

| CNC System | SIEMENS 828D (5-axis prep)/MITSUBISHI M80B (high-speed)/Fanuc Oi-MF Plus (cost-efficiency) |

| Chip Management | Conveyor or spiral chip removal systems for unmanned operations |

| Coolant Solutions | Through-spindle coolant (40 bar) for deep cavity machining |

| Automation Readiness | Robot interface ports for pallet changers or FMS integration |

Why Engineers Choose V855?

Scenario 1: Aerospace Turbine Blade Production

-

Challenge: Thin-wall deformation in titanium alloys

-

V855 Solution:

-

12,000 RPM direct-drive spindle + 48 m/min rapid traverse reduces thermal stress

-

±0.005mm repeatability ensures blade profile consistency

-

Scenario 2: Automotive Die & Mold Manufacturing

-

Challenge: Multi-surface hardening steel machining

-

V855 Solution:

-

7.5kW belt-drive spindle delivers 450 N·m torque at low RPM

-

HIWIN 45mm Y/Z-axis guides handle interrupted cuts

-

Recommended News